A Focus on Humans at High-Tech Souki Systems

Economy Science Technology- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Modern Mechanical Puppets

Souki Systems Co., Ltd., is a venture-capital firm located in the manufacturing city of Higashi Osaka. A specialist in miniature robots and IT devices, the company is also putting a strong emphasis on training the next generation of systems engineers.

“Systems development is all about combining multiple parts with different functions. Our job is to bring them all together to produce a system that performs a single function,” says Ogimoto Kenji, the company president. “Each part has its own technology and function, but the overall structure is what makes up the system. It’s the same for cell phones, bullet trains, robots—you can’t get to the root of a malfunction unless you understand the system as a whole. Robots contain all kinds of systems—microcomputers, sensors, and mechanisms of all kinds—but fundamentally they are based on the same kind of framework as satellites and rockets. In a sense, a rocket is just a flying robot.”

Despite the cutting-edge technology being developed in many fields in recent years, Ogimoto observes, it is impossible to get a machine to work without an understanding of the overall system. But Japan is home to a technology that can be considered the prototype for all these systems: the mechanical puppet.

“A mechanical puppet is a basically a primitive kind of robot. It uses a system made up entirely of springs and gears to give it movement. It works without any built-in computer or sensors. Our ambition is to bring this traditional Japanese craft into the modern era.”

At the center of these efforts is the company’s Souki School of Engineering.

“I used to work in space development, and for five years I worked on a project to support SMEs in the satellite-building business. The people in these companies have extremely specialized skills in their areas of expertise, but they were struggling to use their skills effectively in satellite development. It’s a perfect example of a field in which it’s vital to understand the whole system. It’s not so much mastery of the disparate technologies that’s important, but the system technology—that understanding of how the whole thing fits together.”

Ogimoto says it was this experience that made him realize how vital it was to train systems engineers from an early age.

“You learn the technology by making mistakes and making small improvements. It’s a gradual process of trial and error. You make small rockets and gradually acquire the skills you need. The main aim of the company is to train the next generation of young systems engineers.”

Cultivating Young Talent

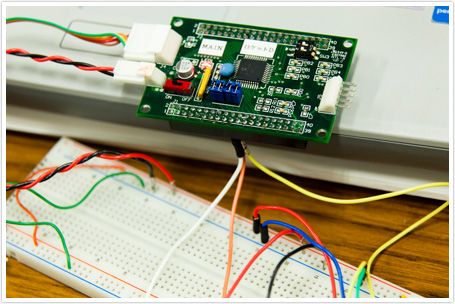

At present 16 young people are enrolled at the Souki School of Engineering for the year under Osaka Prefecture’s “emergency employment measures,” designed to help create new jobs. The research and development offices where they work are busy experimental “test sites” crammed full of prototypes and tangled wiring. The students are divided into groups and assigned to work on building rockets, electric-powered wagons, or satellites. The workspace is a lively hub of activity and passionate debate and conversation. Remarkably, only one of these young people specialized in science subjects at school.

“Of course, learning systems technology isn’t easy, and they all struggled a bit at first. Even now they surprise me sometimes with the basic questions they ask. But we’ve worked to create a learning environment that doesn’t rely on one-sided instruction. The idea is for students to find the answers themselves. Japanese people are good at thinking problems through. They tend to stick at a problem until they come up with a solution. It’s that spirit that has sustained Japanese craftsmanship over the years. If someone is finding the process difficult, we try to find a position that suits that person’s strengths. It’s an engineering school modeled on the terakoya temple schools of premodern Japan. We take a very patient approach.”

Following an initial period of on-the-job training, the students are introduced to every stage of the process of putting together a program and finally making the robots and objects move. Unlike other companies, Souki Systems does not split its workers into different divisions responsible for hardware, software, and design. Instead, the firm allows the entire staff to be involved in each project. This is the perfect system for cultivating the imaginations and practical skills of its young trainees.

Products and Personnel

But there is more to Souki Systems than just training. The company sells the products that result from its research and development efforts. One such product is an electric-powered wagon designed to facilitate factory automation.

“It moves along the line at ground level to transport materials automatically at the push of a button. A version equipped with external sensors is in the test stage now. We’re hoping it can be used as an electric-powered wheelchair. The same technology can also used to make carrier robots.“

When the product is delivered, the company advises the customer of the need for people with a good understanding of the system to ensure that the automated line is properly maintained. This has a synergistic impact, as the young employees are sent out along with the products.

In October 2011, the rocket team succeeded in launching a rocket in Wakayama Prefecture. The technology and experience developed are now being put to use in a project to develop a vertical takeoff and landing aircraft. Currently undergoing tests, the aircraft is controlled by a global positioning system and has an electric motor that enables it to fly straight up and down to a limited extent. It is being used on a trial basis to enable maintenance to be performed on electricity pylons. Other uses include collecting information on the condition of the undersides of old bridges and monitoring the outer walls of tall buildings. Products like these should enable Souki Systems both to foster first-rate young workers and to establish a new era in manufacturing.

With assistance from Wakayama University, a successful rocket launch was carried out in October 2011.

Expanding Beyond Japan

When Souki Systems was founded, the goal was to achieve ¥10 million in sales within three or four years. Four years later, in 2011, the company’s sales were already in the range of ¥50 to ¥60 million.

“No matter what we’re making, we focus on the system. This means that many different elements are needed. We’ve built them up in a balanced way and put our experiences to good use. That gives us the confidence to respond to the wide range of requests we get from customers today. We are in the business of creating systems, offering clients proposals that start from the original specifications. As a result, we also have confidence in our ability to help cultivate talent.”

This flexibility and adaptability, unique to smaller enterprises, allows the firm to respond individually to clients’ needs. This is starting to attract attention from businesses overseas as well.

“The people who come to us for training from overseas are all amazed to see what our actual business activities are. Our business model is time-consuming and in the past would have been extremely difficult to achieve. When we first started we were told by the examiner we rented our office from that there was no market for our business. I told him I would create the market myself. I was very determined. As small as we are, we’ve succeeded with a business that people thought wouldn’t work, because we’ve cultivated a spirit of craftsmanship that’s been built up from the bottom starting with our workers.”

The company’s ongoing efforts to create business opportunities out of craftsmanship and technology have won the support of a number of major educational institutions, including Ritsumeikan University, Osaka Prefecture University, Wakayama University, and the Shizuoka Institute of Science and Technology. Local government, businesses, and nonprofit foundations and dozens of neighboring businesses have also lent their assistance. In time, Ogimoto says he hopes to form partnerships and cooperative arrangements with companies overseas as well.

By training a new generation of workers from the ground up, Souki Systems is broadening the base of Japanese craftsmanship. The company is taking the lead in offering a pioneering vision of the role that business will play in the future, and putting it into practice.

A Message from the Company President

A Message from the Company President- President Ogimoto Kenji with the Chinese character sō, meaning “to create.”

We don’t make components: Our company is all about building systems. Our work is order-made, right from the initial proposal. We work to “create” a system from the ground up. We present ideas, design systems, and refine concepts.

I believe that the experience we have built up gives us the ability to solve whatever requests clients may have. Eventually, I would like to establish a group by forming cooperative relationships with the businesses that use our systems. To help us achieve that, right now my job involves putting together the frameworks and mechanisms for our work and building relationships with the people we want to collaborate with in the future.

- Corporate Data

-

- Company name: Souki Systems Co., Ltd.

- Address: (Headquarters) 2106 Creation Core Higashi Osaka South Facility, 1-4-1 Aramoto Kita, Higashi Osaka City, Osaka Prefecture, 577-0011 (Development Office) 1201 Neoheights Uchihonmachi, 2-4-10 Uchihonmachi, Chūō-ku, Osaka 540-0026

- Representative: Ogimoto Kenji, President

- Business: Development of information technology devices; assisting development and sales of devices incorporating computers and sensors, factory automation. Souki School of Engineering: training of systems engineers through craftsmanship; development of miniature robots: airborne robot systems, experimental rockets, satellites

- Capitalization: ¥13.5 million

- Employees: 6

- Website: http://www.souki-co.jp/

(Originally written in Japanese by Nihashi Ayano. Photographs by Matsumura Takafumi.)

Mechanical doll systems rocket SMEs satellite Souki Systems engineering school electric-powered wagon