Top-Class Wheelchairs Made by OX Engineering

Economy Lifestyle- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Wheelchairs for the Real World

OX Engineering, a company based in Chiba Prefecture, is dedicated to manufacturing and selling equipment that improves the lives of the physically disabled, with a focus on wheelchairs. The company receives orders for its custom-made wheelchairs not only from people in Japan but from customers around the world, including athletes who compete in the Paralympic Games.

The founder and president of OX Engineering, Ishii Shigeyuki, is acutely aware of the needs of the disabled because the former professional motorbike racer suffered a serious injury during a test run and has relied on a wheelchair for his mobility ever since. The first wheelchair he received from the hospital after the accident, however, did not suit him at all. Compared to motorbikes, which are built for speed and tailored to each individual rider, the hospital wheelchair was designed for general use and did not take the needs of the individual into consideration.

Unable to find a wheelchair that satisfied him, Ishii built one himself using equipment from his motorbike company. He used his custom-made wheelchair during a trip to a motorbike show in Germany, and journalists there praised its design. This was the impetus for Ishii deciding to start a business to create wheelchairs based on each user’s needs.

Yamaguchi Takashi, the company’s vice president, explains more about the business focus of OX Engineering:

Vice president of OX Engineering, Yamaguchi Takashi, explains that the starting point of the business was the “desire to overturn conventional wisdom on wheelchair design and functionality.”

Vice president of OX Engineering, Yamaguchi Takashi, explains that the starting point of the business was the “desire to overturn conventional wisdom on wheelchair design and functionality.”

“In Japan, disabled people can receive wheelchairs under the social security system. So most wheelchairs used in Japan are ones that can be purchased using that benefit. Although these wheelchairs certainly have all of the necessary functions that you would expect, they don’t have much more that that. Such wheelchairs come up short when it comes to meeting the usability and design needs of individuals after they leave the hospital. Even if people have a physical disability, it is not appropriate to view them as sick, because in other respects they are healthy. We believe that it is vital to provide them with the kind of wheelchair that makes it easier for them to get out and about.”

Customizing Wheelchairs to Suit Individual Needs

Yamaguchi goes on to explain what functions on a wheelchair can enhance a person’s mobility:

“Wheelchairs provided by hospitals are built with the seat’s width, depth, and height slightly larger so that all sorts of people can use them. For this reason, they’re heavy and can’t be adjusted. Ordinarily, adding an adjustment function to a wheelchair increases its weight. However, our wheelchairs use aluminum components for the adjustable parts, which allow them to be lighter than standard wheelchairs, even those that are adjustable. We design wheelchairs that are lighter, more compact, and allow greater freedom of movement. And we add features that are designed for each individual. Our wheelchairs are highly maneuverable, even in cramped spaces, and can be easily loaded into a car. Our aim is for design that reflects functionality, so we don’t tie ourselves down to fixed ideas about what a wheelchair should be like.”

The practicality of the company’s wheelchair design is clear from a look around the company’s office, where employees in OX Engineering wheelchairs easily and quickly move around on the job.

There are many wheelchair users at OX Engineering, so these employees can propose ideas for new products based on their everyday experiences.

There are many wheelchair users at OX Engineering, so these employees can propose ideas for new products based on their everyday experiences.

“The important thing is for the user to have as much freedom to move as possible,” Yamaguchi explains. “To ensure that the user can look forward and move both arms freely we consider all sorts of factors, including the proper angle for the seat surface and the overall height of the wheelchair. Situations differ depending on the extent of a person’s disability, but if users can have that freedom of movement it is much easier for them to interact with other people and to perform their work, which in turn makes them more motivated to be active in society.”

Wheelchairs are built in a modular fashion, allowing users to choose parts freely from the available stock, such as the vividly colored pipes and tires above.

Wheelchairs are built in a modular fashion, allowing users to choose parts freely from the available stock, such as the vividly colored pipes and tires above.

Inside the OX Engineering wheelchair plant is a wide array of frames, tires, and other components. This reflects the fact that wheelchairs are assembled at the plant in a modular fashion by measuring the user’s dimensions and assembling the appropriate pre-made components. And for the painted wheelchair parts, the user can choose from 100 different colors.

Due to the almost limitless variety of sizes, colors, functionality, and other options, each assembled wheelchair is unique. The company has put in place a production line capable of efficiently handling orders on the basis of its properly maintained stock and highly proficient technicians. Thanks to this system the company can tailor products to suit each customer. The production line is so efficient that products can be delivered in just three weeks—an exceptionally short delivery time for this industry.

Along with functionality, safety is another key commitment for OX Engineering, as Yamaguchi explains:

“We have a testing laboratory at our plant to gauge wheelchair quality. The machines that we use to do this testing are built in-house. If we were to outsource testing, it would increase costs and require more time to obtain the results. The processes of manufacturing and quality improvement inevitably involve trial and error. Our strength is that we can do this all internally.”

One piece of equipment in the testing laboratory is the double drum winch, which gauges the durability of a wheelchair and how its frame is affected by speed, bumps, and uneven road surfaces. The piece of equipment has a rolling surface with ridges and bumps on which a wheelchair, with a 100kg weight in its seat, moves. Under Japanese Industrial Standards, a wheelchair frame must be able to withstand 200,000 revolutions on the double drum winch, but the minimum standard at OX Engineering is 300,000 revolutions.

As part of its commitment to safety, the company will adjust or replace parts after a customer purchases a wheelchair; and each of the parts is subject to detailed tests as well. Moreover, the company examines how customers use their wheelchairs, such as their movement and posture, and these results are incorporated into tests that recreate these individual ways of using a wheelchair.

Improving Quality of Life for the Disabled

Customers’ requests are diverse since there is an almost infinite variety of disabilities and many different ways of using a wheelchair.

“We get all sorts of requests,” Yamaguchi notes. “For example, sometimes we are asked to change the length of an armrest or the size of a footrest. The customer’s preferences are the most important thing, but we can’t do everything that is asked of us because sometimes what the user wants is determined by the traditional concept of a wheelchair.”

What Yamaguchi means by the “traditional concept” is the mindset of assuming that the conventional way of doing things is the most natural and appropriate. In fact, many of the parts used in standard wheelchairs can prove to be unnecessary. After scrutinizing the normal way of doing things, OX Engineering began to realize that some parts are simply unnecessary, and proposed a new way of assembling a wheelchair without them. The company’s customers have been happy with the results, with many saying that a wheelchair becomes more comfortable as a result.

One thing that customers often ask for is a lightweight wheelchair. Meeting this request involves deciding whether to remove some parts used for adjusting the wheelchair or to use lightweight materials. Yamaguchi explains more about the factors that have to be taken into consideration:

“In the end, when you think that corrections are necessary in response to a user’s muscle strength or degree of disability, it’s better to leave the adjustment function on the wheelchair. In this case, we maintain the strength of the parts used for adjustments, while removing unnecessary components in order to make the wheelchair lighter. The additional effort needed to create such a wheelchair requires more resources so the price naturally increases, but we think it is worthwhile for users because the ultimate aim is to make their everyday life easier.”

Expanding Globally

Yamaguchi attends exhibitions overseas, with an eye to expanding the company’s share of the global market.

“In Asia, we have built ties with dealers in Taiwan, South Korea, and other countries where we are selling new models. In Thailand, we are marketing second-hand wheelchairs from Japan that customers have traded in. At the moment, the number of expensive new models that we are selling there is quite low. But as the Thai economy expands, it’s quite possible that customers who bought a second-hand wheelchair the first time will purchase a new one the next time around.

For racing wheelchairs, the design is tailored to each individual user, and based on these designs parts are made to construct the wheelchair.

For racing wheelchairs, the design is tailored to each individual user, and based on these designs parts are made to construct the wheelchair.

“In Europe, we are receiving orders for our custom-built racing models, mainly from track-and-field athletes. When we started this business in Japan, we offered racing wheelchairs to top-class athletes free of charge. This not only allowed us to obtain valuable feedback from the athletes, but also opened up opportunities to create wheelchairs for everyday use for those who liked our racing models. In this way, we established ourselves as a racing wheelchair brand, and then expanded into making wheelchairs for everyday use and into foreign markets.”

OX Engineering systematically makes top-class, custom-made wheelchairs, without being bound to conventional ideas and methods. This approach has put the company in a good position to contribute positively to social welfare in the years ahead.

A Message from the Company’s Vice President

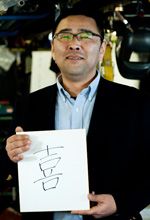

Vice President Yamaguchi Takashi with the Chinese character ki, meaning “joy”—and more particularly, joy related to the creation, use, and sale of wheelchairs.

In recruiting employees, I’m more interested in someone who is keen to make wheelchairs for competitors in the Paralympics, than someone looking to “contribute” to the society welfare sector. Business isn’t about volunteering, so contributing can’t be the main focus. Instead, we have to strive to have our products meet the needs of the market, which requires a joyful spirit.

Many of our employees are passionate about motorbikes, bicycles, and other vehicles. For instance, as a side endeavor, one of our employees responsible for planning wheelchair designs has constructed a prototype folding bicycle that uses the same folding mechanism used for our wheelchairs. This started a whole new business line. You can’t sell wheelchairs unless you love making things, are enthusiastic about your products, and have a strong desire to see people using them. I believe that the joy of doing such things is amply apparent throughout our company.

Corporate Data

Company name: OX Engineering Co., Ltd.

Address: 2186-1 Nakatachō, Wakaba-ku, Chiba City, Chiba Prefecture, 265-0043

Representatives:

Ishii Shigeyuki, President

Yamaguchi Takashi, Vice President

Business: Manufacture and sale of wheelchairs and design of equipment for the disabled

Capitalization: ¥150 million

Employees: 40

Website:http://www.oxgroup.co.jp/

(Originally written in Japanese by Nihashi Ayano. Photographs by Matsumura Takafumi.)

SMEs OX Engineering Paralympics Chiba racing competition wheelchairs Ishii Shigeyuki Yamaguchi Takashi double drum winch