Industrial Strength 3D Printers: Matsuura Machinery

Economy- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Lumex Machine Cuts Costs and Labor Time

Matsuura Machinery Corp., located in Fukui Prefecture, developed its first hybrid metal laser sintering and milling machine back in November 2002. The Lumex Avance-25, now in its fourth generation, forms three-dimensional objects one layer at a time by placing a layer of metal powder on the processing table, sintering it with laser light, and then repeating the same process with the next layer. As the object is built up, its surface is simultaneously finished with high-speed milling.

Chief researcher Gotō Motohiro alongside the prototype Lumex machine at the development laboratory of the Industrial Technology Center of Fukui Prefecture.

Chief researcher Gotō Motohiro alongside the prototype Lumex machine at the development laboratory of the Industrial Technology Center of Fukui Prefecture.

Molds made in this way can be finished with much greater precision than by using other methods. The Lumex makes it possible to arrange ducts within a die or mold in any way desired, greatly improving the cooling effect of plastic poured into the mold and raising productivity. On top of this, the objects produced are strong enough for use as finished products, not just interim molds.

The Lumex is the first machine to combine the two jobs of forming and milling in a single unit. As a result, design and processing times that previously took two weeks to one month can be shortened by a third and costs can be reduced by up to half. Because it allows for fully automated operations, the machine can also reduce labor costs. In all these ways, the machine can be a godsend for manufacturers desperate to cut costs.

Amazing Product, Awkward Name

When Matsuura was developing the prototype of the Lumex, the term “3D printer” was not yet in common use. At first the prototype was given the tongue-tripping name, “metal laser sintering hybrid milling machine.” The machines were not quick to catch on because few people were aware of additive manufacturing technology and the cost was prohibitive, at around ¥70 million per machine.

Matsuura Katsutoshi, current president of Matsuura Machinery.

Matsuura Katsutoshi, current president of Matsuura Machinery.

But the situation has changed over the past year or two, with the debut of personal 3D printers sold at electronics stores for as little as ¥100,000 or less. Since these devices build up plastic or other materials and give them shape, it appears at first glance as if they create three-dimensional objects out of thin air. In the media they were hailed as “magic boxes,” and the 3D printer boom took off.

There is growing awareness in society of this technology to create three-dimensional objects. Today the impact of the 3D printer movement can be seen everywhere from the level of personal use to industrial applications. The spread of this technology in Japan has benefitted from the introduction of a national system to subsidize investment in cutting-edge technologies such as 3D printers.

Despite the 3D printer boom, Matsuura had stuck with the name “metal laser sintering hybrid milling machine.” But this year the company finally gave in and changed the name to “hybrid metal 3D printer.” Company president Matsuura Katsutoshi explains: “No matter how much we insisted that our product was a ‘metal laser sintering hybrid milling machine’ or ‘additive fabrication machine,’ most people still viewed it as a 3D printer.”

Video of the Lumex Avance-25 (courtesy of Matsuura Machinery).

Lumex Solves the Problem of Wear

Over the years, the product lineup of Matsuura Machinery has evolved from lathes and milling machines to machining centers (numerically controlled machine tools with automatic tool changing functions)—and now Lumex. Today machining centers account for 95% of Matsuura Machinery’s sales, but Matsuura Katsutoshi thinks Lumex will change the situation. “Inquiries have been increasing recently, and it seems like the new product’s time has finally arrived. We anticipate that Lumex sales will be on the scale of around three billion yen by 2020.”

Lumex was not created in a vacuum. It is the result of efforts to raise the productivity of machining centers. In pursuit of high-speed, high-accuracy machining, the company always ran up against the problem of cutting tool wear at higher speeds, which reduced accuracy.

The question was how to overcome the problem of tool wear. The company’s solution, explains President Matsuura, lay in the possibility of using high-speed lasers to cut the material without contact. “I wondered for a long time whether lasers could be applied to metal machining as a way to avoid the problem of wear and degradation,” he recalls. Around that time the company was approached by the electronics giant Matsushita Electric, today’s Panasonic, about the possibility of jointly developing laser and cutting processes.

The Perfect Partner

For Matsushita, shorter product development times were a matter of vital importance. The company had been working on modeling technology using lasers since the early 1990s. Through trial and error it had developed the basic technology for performing the processes from laser sintering to finishing on a single machine, and had built machines for internal use. However, Matsushita had difficulty getting the machines to perform in the desired way. This led to the company’s decision to approach Matsuura as a potential partner, recognizing the excellence of Matsuura’s machining centers that Matsushita had used as a customer.

Katsuki Kazuo, director of the Industrial Technology Center of Fukui Prefecture.

Katsuki Kazuo, director of the Industrial Technology Center of Fukui Prefecture.

Around that same time the Industrial Technology Center of Fukui Prefecture also began using laser technology for locally produced products, such as textiles, eyeglass frames, and machines. Looking to innovate processing methods, the center applied for a joint project sponsored by the Ministry of Education, Culture, Sports, Science and Technology aimed at mobilizing regional assets. Development of a hybrid metal laser sintering and milling machine fell within that framework, and an industry-government-academia project that included the University of Fukui was launched in December 2000.

Katsuki Kazuo, director of the center and a project member, recalls that time. “It just so happened that our development project to use lasers corresponded perfectly with the timing of the joint initiative of Matsushita Electric and Matsuura Machinery. And the president of Matsuura Machinery at the time, Matsuura Masanori [currently the company’s chairman], was asked to direct our project. So we were fortunate that our group came together to work on laser development at the exact moment that a company based in Fukui was trying to advance the industrial applications of lasers. It may seem random, but I almost think it was fate.”

Panasonic Pioneers Lumex Use

The first to get involved in using Lumex was its co-developer, Panasonic. In mass-producing its home electronics products, the company begins by manufacturing high-precision, durable molds. Metal or plastic is then poured into these molds to produce the various parts and materials.

Making these molds and dies requires great skill and can take up to two months to complete, costing as much as tens of millions of yen. There is no room for error when it comes to producing this fundamental manufacturing technology. And each time a new product is developed, new molds are needed, which can add up to major costs.

Panasonic looked to Lumex as a way to become more competitive globally by significantly reducing costs compared with previous manufacturing methods. The plan was to first use the technology for electrical sockets and ventilation fans, later expanding to include dryers and shavers.

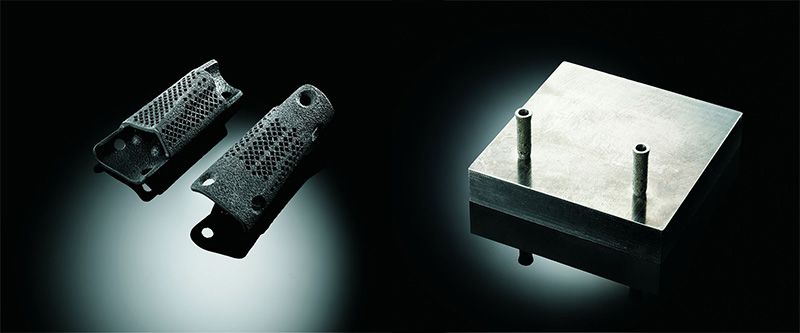

Lumex enables high-quality modeling with a large degree of freedom. It is suited not only to the creation of dies and molds, but also to the manufacture of the metal parts themselves. Some companies have gone beyond using it for prototypes to also employ it for the actual manufacture of parts for automobiles, smartphones, and other products. Lumex also shows promise as a means of manufacturing custom-made parts in small lots. Already it is being used in the medical sector to make artificial bone and dental implants, and demand is anticipated in the aerospace industry for the production of aircraft and aircraft-engine parts, as well as rocket components.

Customized titanium bones (left) and implants (right) made using the Lumex machine. (Photographs courtesy of Matsuura Machinery.)

Customized titanium bones (left) and implants (right) made using the Lumex machine. (Photographs courtesy of Matsuura Machinery.)

Mitsubishi Heavy Industries has been looking into the use of metal 3D printers as a way to manufacture parts for its new flagship launch vehicle for satellites, whose trial launch is planned for 2020. Meanwhile, General Electric and other leading makers of airplane engines are preparing to use these devices in the manufacture of engine parts.

Expanding Global Sales

Exports currently account for 70% of Matsuura’s sales. The company has sales offices in Britain, Canada, Germany, Taiwan, and the United States, along with a distribution network in 31 countries. Matsuura’s sales place it sixty-eighth globally among machine tool manufacturers (as of July 10, 2014, according to a survey conducted by Gardner Business Media).

It was a winding road that has brought Matsuura to its current position as a global corporation, with many bumps along the way. In the 1970s, in particular, the company suffered a double-blow from the so-called “dollar shock” of 1971 that was followed three years later by the “oil shock.” This combination nearly brought the company to its knees.

What saved the company was a vertical machining center (a machining device with the main spindle oriented vertically), which the company developed at that time when its back was against the wall. No one else in the world had created a vertical machine back then; all of the other centers were horizontal types. But the price of Matsuura’s new device was ¥40 million to ¥50 million, placing it out of the reach of smaller businesses.

The plan to develop the vertical machining center stemmed from the advice of Ōga Norio, president of CBS/Sony Records at the time (and later president of Sony). He told the president of Matsuura the importance of “developing products with special characteristics that no one else is developing, particularly ones that are likely to sell well in the United States.” In March 1974, Matsuura launched its first vertical machining center in Japan. Its ¥16 million price tag made it affordable for smaller firms.

The new machine benefited from an order made by the US-based machine tool trading company Methods Machine Tools. Its president at the time, Clement McIver, noticed the new vertical machining center at an exhibition in Nagoya and immediately recognized its potential. Right away, he placed an order for 10 machines, with the intention of buying more later. This was a windfall for Matsuura at a time when the company could maintain itself and its workforce by just selling five units a month. Eventually, a contract was signed to sell McIver’s company 14 machines per year. It was a historical moment for Matsuura.

In the case of its Lumex machine, Matsuura concluded an exclusive sales agreement with Mitsubishi Corporation, and North American sales began in January 2014. The first target was the American die and mold industry, with sales handled by Mitsubishi Corporation’s US subsidiary, MC Machinery Systems (MMS), which has a strong customer base in the North American die and mold industry. Matsuura decided to partner with MMS after determining that special sales knowledge and specialty applications different from those for machining centers were necessary.

Expanding its Product Lineup

Matsuura’s head office and plant is in the city of Fukui, not far from the Sea of Japan. It is the birthplace of the company’s founder and first president, Matsuura Toshio. He returned to his hometown in August 1935 to start a subcontracting shop for lathe parts with the skills he had acquired during an apprenticeship in Tokyo. He was 21 years old at the time.

“Toshio was a charismatic craftsman,” says Matuura Katsutoshi, the grandson of the company’s founder and its current president. “If a machine was good, he knew it immediately. My father [Masanori] also had good intuition as the company’s leader, and was the type to charge ahead once he made a decision. In this way, our first president built the company’s manufacturing foundation, and the second president went out into the world to sell our products and build up the business. My task is to take what they built and make it even stronger.”

The head office of Matsuura Machinery, surrounded by rice paddies in Fukui Prefecture.

The head office of Matsuura Machinery, surrounded by rice paddies in Fukui Prefecture.

But Matsuura’s Lumex machine already has a rival. The Yokohama-based company Sodick, ranked thirtieth globally among machine tool makers, will begin sales of a new metal 3D printer in October 2014. Matsuura welcomes this competition, saying that it will increase the the number of users of of metal additive modeling and bring users more options. Matsuura currently has just one Lumex model, but it intends to develop a whole product lineup, including larger models, to beat out its rivals.

Matsuura is also participating in a national project that began in fiscal 2014 to develop technology for a world-class, next-generation industrial 3D printer. The aim is for the machine’s accuracy to be five times greater, and its modeling speed ten times faster, than the level of machines made overseas. If the company reaches these ambitious goals, its global presence is likely to expand further. Already President Matsuura Katsutoshi spends nearly a third of the year traveling around the world to promote sales, but he will probably be earning even more frequent flier miles in the years ahead.

Corporate Data

Company name: Matsuura Machinery Corp.

Head office: 1-1 Urushihara-cho, Fukui, Fukui Prefecture, 910-8530

Representative: Matsuura Katsutoshi

Business: Manufacture and sales of machine tools (machining centers); manufacture and sales of hybrid metal laser sintering and milling machines; sales of CAD/CAM systems

Capitalization: ¥90 million

Employees: 292

Tel: (0776) 56-8100

Website: http://www.matsuura.co.jp/english/index.html

| 1935 | Matsuura Machinery founded. Subcontracting of lathe part machining begins. |

| 1936 | Production of lathes launched. |

| 1940 | Manufacture of lathes halted under wartime production system. |

| 1945 | Katsumi Plant destroyed in an air raid. No. 2 plant closed. |

| 1945 | End of World War II. |

| 1957 | Production and sales of milling machines begins. |

| 1960 | Reorganized as joint-stock corporation. |

| 1961 | Begins production and sales of world’s first program-controlled milling machines. |

| 1964 | Numerically controlled milling machine developed. |

| 1974 | Production of vertical machining centers begins. |

| 1985 | Ties up with US-based company National Machinery. |

| 1988 | Gains a 20% share of Elliot Machinery (Canada) and of Beaumont Machine Tools Limited (Britain). |

| 1991 | Matsuura Technical Center Europe established in Britain. |

| 1993 | Total number of machining centers shipped reaches 10,000 units. |

| 1996 | Matsuura Machinery, a European production and sales base, established in Leicestershire, Britain. |

| 1999 | Production and sales begin of linear motor machines with linear motor drive. |

| 2001 | Matsuura Europe (MEG) established in Germany. |

| 2002 | World’s first “metal laser sintering hybrid milling machine” developed jointly with Matsushita Electric. |

| 2003 | MMTS, a sales base for North America, established in Massachusetts. |

| 2009 | A 5-axis multi-tasking machining center, Cublex-63, developed. |

| 2013 | Matsuura Machinery (MMU) established in Minnesota. |

| 2014 | Participates in the Ministry of Economy, Trade, and Industry’s project to develop a next-generation industrial 3D printer. |

(Originally written in Japanese by Nagasawa Takaaki. Banner photograph of Urushisaki Yukinori, general manager in Matsuura Machinery Corporation’s Additive Manufacturing Technology Engineering Division.)

industry technology Lumex Avance-25 die mold fabrication machine Fukui Prefecture Matsuura Machinery