Aiya: Innovation and Tradition Bring Matcha to the World

Economy Culture- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

The Craft that Goes into a Matchless Cup of Matcha

Blessed with a mild climate, the city of Nishio in Aichi Prefecture is famous as Japan’s major producer of the finely powdered green tea known as matcha. Used in the traditional tea ceremony, matcha is generally regarded as the pinnacle of Japanese teas, offering a rich and subtle range of deep, sweet flavors. And the matcha grown in the rich, fertile soil of the Yahagi River valley is the finest of all. Aiya Co., Ltd. has been producing and selling tea here for more than 120 years. Recently, the company has expanded far beyond its traditional market, brining the fine bouquet and flavors of matcha tea to new audiences around the world.

What are the qualities that have enabled Aiya to take a product as distinctively Japanese as matcha tea and transform it into a new global standard?

Only traditionally trained craftsmen have the skills necessary to maintain the hand mills used to grind the leaves.

Only traditionally trained craftsmen have the skills necessary to maintain the hand mills used to grind the leaves.

Just as important as quality is safety. With concerns over food safety high among the public, consumers have strict standards when it comes to the use of chemical pesticides and contamination during the production process.

“If there are bacteria in the air, we have to be very stringent about sterilizing everything with heat. But this spoils the quality of the leaves. For this reason we keep the matcha in what we call the ‘clean room,’ a sterilized environment where humidity and temperature are kept at a constant level. We have excellent standards of sanitation throughout our factory area, too, to make sure that there is no contamination during the production process.”

Like any company, Aiya could shorten the production process and prioritize efficiency over quality and safety. But the people at Aiya are too proud of their product to cut corners. This is a company that is determined to compete on a global level without compromising the high levels of craftsmanship honed over the course of generations.

“When it comes to matcha, we are professionals,” Sugita says. “And it’s a golden rule in every business that a professional must never take advantage of an amateur. We want to do everything we can to offer a product of outstanding quality. That means no cutting corners. This spirit of dedication is what supports Japanese craftsmanship. I don’t want to cheat our customers by offering counterfeit matcha.”

Aiya uses the same rare stone mills and exactly the same production processes in its new undertaking in China as back home in Japan. This dedication to detail is an essential part of Aiya’s corporate philosophy, and a core element of what the company president calls “Aiya-ism.”

But no matter how impressive a company’s corporate philosophy may be, there is no way to guard against natural disasters. The triple disaster that hit Tōhoku in March 2011 was particularly devastating for the Japanese food and drink industry. The nuclear crisis in Fukushima made consumers around the world wary of Japanese produce, regardless of what part of the country it happened to come from. Many companies never recovered from the blow.

Giving Customers the Information They Need

Running checks on color variation, moisture, and particle size is an essential part of ensuring high quality.

Running checks on color variation, moisture, and particle size is an essential part of ensuring high quality.

“Consumers overseas tend to have very high standards when it comes to product safety,” notes Sugita. “We offer a product that is affordable and delicious while encapsulating traditional Japanese cultural values. But that alone is not enough. That is why we put so much effort into informing the public about our safety and production procedures.”

Aiya takes safety seriously. After the disaster last March, Aiya paid a German company to carry out thorough tests for radiation on all its tea.

The company has also received kosher certification, which comes in useful when exporting to the American market.

“Jewish communities have very stringent food regulations. They will not approve any ingredients or production methods that contravene religious teachings. A team of inspectors visits our factory every year to make sure that our tea satisfies Jewish dietary laws.”

Another team of inspectors visits every year for the company’s accreditation as an organic producer. The company has also received the highest accolades for its dedication to safety, from the tea plantation to the final stages of the production process.

This reputation for unstinting safety has brought Aiya international success. As well as managing thriving overseas operations in China and the United States, the company now markets its teas in Belgium, Canada, France, the Netherlands, and the United Kingdom.

Green Tea with Whiskey, Cinnamon, Sugar . . . Anything Goes!

Safety is of course an indispensable criterion for any company hoping to expand overseas. But there is another reason for Aiya’s international success. Its flexibility and openness to new ways of enjoying its product have helped the company’s matcha offerings to assimilate easily into local cultures around the world, as Sugita explains.

“During my travels, I noticed that the markets for matcha in Europe and the United States were different. In America, people are more open to the idea of matcha if it is presented with vanilla or milk. So at exhibitions and similar events we always make sure to offer things like matcha au lait, matcha ice cream, matcha chocolate, and so on. In Europe, on the other hand, there is a well-established custom of drinking herbal teas, and people tend to see matcha as part of that category. For that reason, we encourage people to try matcha with their favorite choice of mixers—whiskey, cinnamon, sugar, salt, whatever they like. What’s important is to keep listening to customer needs and preferences.”

In ancient China, tea was regarded as a kind of medicine. The spoons used for measuring out tea are the same as those used for traditional Chinese medicines. The same is true of the jars in which tea is stored and the mills used to grind it. The concept of matcha as a health product has been enthusiastically embraced in many countries in the West, where health consciousness is particularly high among modern consumers.

_Matcha ice cream, yogurt jelly, and soufflé. Matcha and Japanese sweets are now being enjoyed around the world.

Sugita believes that the passion for Japan’s tea has gone global. “I was once invited to a party at someone’s house in Germany, where the host proudly prepared some matcha tea. Although his technique might not have passed muster among tea ceremony aficionados, he was very proud to identify himself as a matcha drinker. This tea is a Japanese health product with a thousand years of history, he said, imbued with the spirit of Zen. People in Europe and the States care a lot more about health issues than people in Japan. This is key for us.”

The company is proud of its long history and its reputation for quality. Perhaps because this basic foundation is so secure, Aiya doesn’t need to worry about the unfamiliar ways in which its products may be enjoyed overseas, the president says with a smile.

“At the moment roughly a fifth of our sales come from overseas. Our strategy is based on the idea of balance—remembering where we came from and valuing the local cultures of foreign markets at the same time. If we continue to maintain this balance, I am confident that our business will continue to expand in the future.”

Aiya values the traditions and the respect for basics that have sustained the company’s success for more than a century, but also has the flexibility to adapt to local cultures and meet consumer demands in new markets. At the same time, the company works to reassure customers by publishing information about its safety procedures. Aiya’s contemporary twist on tradition offers an example for more companies to follow in today’s competitive environment.

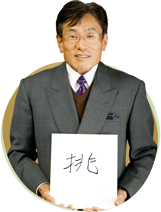

A Message from the Company President

The character I have chosen to represent the company is chō (挑), the first character of chōsen (挑戦), or “challenge.” I have always been a big admirer of Matsushita Kōnosuke, the founder of Panasonic. I want the company to be positive in everything it does and to accept the challenges, whatever they may be. As Matsushita used to say: Don’t sit around waiting till death catches up with you; get out there and do it!

The character I have chosen to represent the company is chō (挑), the first character of chōsen (挑戦), or “challenge.” I have always been a big admirer of Matsushita Kōnosuke, the founder of Panasonic. I want the company to be positive in everything it does and to accept the challenges, whatever they may be. As Matsushita used to say: Don’t sit around waiting till death catches up with you; get out there and do it!

We work hard to instill this spirit in our employees. We have a meeting every morning at which we drink tea together and report honestly on the state of the company. I emphasize that the final responsibility lies with me. I try to create a corporate atmosphere in which employees are encouraged to come up with their own solutions and ideas, and act on their own initiative.

As part of developing a profile for our company in overseas markets, all our employees have taken part in our mangrove-planting program. Sharing the sense of achievement that comes from meeting our planting targets helps people to feel that they can meet whatever challenges come their way. This experience of challenge and achievement is an important part of our training.

- Corporate Data

-

- Company name: Aiya Co., Ltd.

- Address: 15, Yokochō Yashiki, Kamimachi, Nishio-shi, Aichi 445-0894

- Representative: Sugita Yoshio, President

- Business: Production and sale of matcha and other tea products

- Capitalization: ¥30 million

- Employees: 75

- Website: http://www.matcha.co.jp/

(Originally written in Japanese based on an interview by Nihashi Ayano. Photos by Matsumura Takafumi.)

SME Zen Radiation food safety Aiya tea matcha mill tradition safety Aichi matcha milk matcha ice cream organic Nishio