Advanced System: Keeping Noise, Vibration to a Minimum

Economy Science Technology- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Forward-Looking Technology

The Japanese company Advanced System, or AS for short, was established back in the late 1970s under the name “Air Spring.” At the time, people in Japan were becoming aware of the severity of the problem of pollution. AS put its heart and soul into anti-pollution measures, but not in the usual sense of addressing air or water pollution. Rather, it focused on using sound- and vibration-proofing to create labor and production environments where people could work safely and comfortably. In other words, rather than the natural environment, the main concern for AS has been the workplace environment.

Hayakawa Masamitsu, the president of AS, has spearheaded efforts to address problems related to the labor and production environment.

Hayakawa Masamitsu, the president of AS, has spearheaded efforts to address problems related to the labor and production environment.

The “base isolation” technology developed by AS, which protects structures against the force of earthquakes, has been adopted by many countries in recent years. This technology safeguarded many industries and objects from the destructive force of the earthquake that struck Japan on March 11, 2011. The company’s foresight in developing this key technology has earned AS praise from clients located around the world.

Given the company’s global reputation, a visitor to the small AS workshop is struck by the scarcity of machines and employees. “We hardly make anything at all at the workshop,” explains Hayakawa Masumitsu, the president of AS. What the company makes is not physical goods but advanced technology itself.

Let’s take a closer look at how this firm, committed to the highest standards of professionalism, carries out its work.

Preventing Deafness in the Workplace

When AS was established, in 1978, it concentrated on the rubber industry, only later shifting its focus to the workplace environment, as President Hayakawa explains:

“Air Spring, as we were originally called, produced vibration-proofing devices using air springs, which is one segment of the rubber industry. We created Advanced System by branching out from that segment to create an independent business with a focus on developing new technologies. This endeavor was based on our awareness of the potential for acquiring new skills and obtaining new customers in this area. At first, our main products were sound- and vibration-proofing for press manufacturers [manufacturers of forge presses for automobile bodies].”

A sound-proofing device; a dual structure of sound insulation and sound absorbing materials inside the doors prevents sounds from leaking out.

A sound-proofing device; a dual structure of sound insulation and sound absorbing materials inside the doors prevents sounds from leaking out.

Generally speaking, soundproofing for a forge press involves creating walls and specially designed boxes to isolate the noise it generates, while vibration-proofing requires the use of special devices to ensure that vibrations coming from above are not transmitted downward. However, when AS first set out on its own in this field, the need for such devices was far less than had been anticipated. At the time, the basic priority for companies was the manufacturing of equipment, so it was normal for them not to allocate funds to address workplace environment concerns. This began to change in 1967, though, when Japan’s Environmental Pollution Prevention Act stipulated for workplaces a maximum noise level of 85 decibels [a level that will not lead to eventual deafness among workers not wearing earplugs].

“The first thing we had to emphasize was soundproofing,” says Hayakawa, “because a noisy workplace can lead to deafness. Our basic aim was to make sure that workers did not end up losing their hearing. And it turned out, eventually, that in pursuing this goal we were able to begin meeting the needs of the time; although it is only in the last 10 years or so that people have really seen the need for improving the workplace environment.”

Later, the tide of the times began to change again, when interest turned to vibration-proofing. This reflected society’s emerging awareness of the need for skills to cope with a crisis of any size.

Earthquake-Tested “Base Isolator”

Along with soundproofing and vibration-proofing, AS’s other key area of expertise is base isolation. This involves the use of a device to prevent energy from an earthquake or other source from being transmitted upwards from below. Last year’s Great East Japan Earthquake put this base isolator device to the test.

“We jointly developed a base isolation system for a semiconductor plant and put it in place on a trial basis,” Hayakawa recalls. “When the earthquake struck, almost everything that had not been seismically isolated using this system was destroyed; whereas the isolated equipment suffered no damage at all. This attracted a great deal of attention. And now we have so many orders that our production can’t keep up.”

Base isolators are now also being used to protect fragile objects, such as works of art or server equipment. “In the case of use at an art gallery,” Hayakawa explains, “it is important for the isolation device to be as small as possible so that it’s not noticeable. You can’t have a device that sticks out.” One example of an unobtrusive base isolator is the AS-produced device installed at the National Museum of Western Art in Tokyo to safeguard Auguste Rodin’s sculpture, The Thinker.

President Hayakawa demonstrates the functions of the base isolator device used to protect works of art.

President Hayakawa demonstrates the functions of the base isolator device used to protect works of art.

Hayakawa explains more about the basic principles for the base isolator used to protect the sculpture:

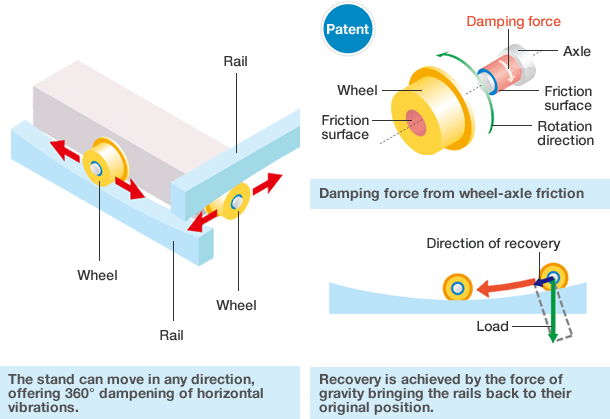

“The stand on which an artwork is placed is the same shape as a normal display stand, but it has built-in wheels on rails pointing outwards in four directions. If an earthquake occurs, the wheels and rails move in the manner of a pendulum. The two-tier structure allows movement backward and forward, and also left and right. The movement of the vibrations, including oblique vibrations, in all of those directions allows them to be dissipated.”

Structure of the TCR base isolator

The special feature of AR’s Tuned Configuration Rail base isolator is its simple, adjustable wheel-and-rail structure, which operates according to the same principle as a pendulum.

Fostering Employee Professionalism

Creating a forward-looking product like the base isolator requires considerable organizational prowess. AS required a corporate structure that would allow it to be proactive in terms of selling technology itself as its product.

“We outsource 99% of the actual manufacturing and make almost nothing in our own workshop,” Hayakawa explains. “What this means is that we narrow our focus down to overall product planning (from the blueprint stage to implementation), progress management, and cost optimization; and we patent these operations. This is our strategy, and most of our patents are related to base isolation.”

AS, in other words, is a technology-intensive collective. Hayakawa goes on to describe the type of employee training necessary for the company’s approach:

“There is no way to foster young employees if a company leaves everything up to its president. When it comes to a particular technology, our approach is to wait until the time is right and then select the appropriate employee to handle everything related to it. It’s like saying, ‘Right, now you’re the general manager.’ Employees placed in this position may feel hesitant at first, but it is only be assuming such responsibility that they can develop themselves; otherwise we’ll end up with a culture of dependence. Our employees learn by experience, rather than by receiving guidance.

“We want all of our technicians to become professionals with extensive planning capabilities when it comes to soundproofing, vibration-proofing, as well as base isolation; and also with regard to the ability to deliver things on time. In short, employees need to be able to hold their own on the shop floor of a manufacturing plant.”

Importance of Loyalty and Compassion

Hayakawa describes the AS company spirit as “rather old-fashioned,” as he explains:

“I value the concepts of loyalty and compassion. Some people feel a debt of gratitude to whatever company they work for, while others just think of it as a job. It seems a bit sad to me, though, when a sense of gratitude is lacking, so I’d like our employees to have a bond of loyalty and compassion to AS. And when it comes to our customers, I don’t want them to only view us as selling tangible objects: I want them to have the sense of purchasing the value of reduced noise and vibrations and of safety in the event of an earthquake. What we are providing them is the value of new solutions to problems.”

After the March 11 earthquake, AS received many words of thanks from its customers, including overseas clients. Building on this positive response, the company is now expanding its operations overseas, opening an office in Beijing in 2011. The focus for the new office will be base isolators for art galleries and IT servers, but there are also plans to speed up activities for the sound- and vibration-proofing of industrial applications. The base isolation technology AS is introducing in the United States, Brazil, Africa, the ASEAN region, and other parts of Asia is likely to constitute a burgeoning business.

AS, in short, is a company that solves problems for its customers in a way that suits the risk management needs of their specific workplaces. With its flexible approach, combined with technical prowess that reflects both passion and rationality, the company is poised to build on its strengths moving forward.

A Message from the Company President

A Message from the Company President- President Hayakawa Masamitsu with the Chinese character jō, meaning “passion.”

- The focus at AS is on passion combined with a sense of loyalty and compassion. What has supported us as a company is not so much the depth of my own passion as president but that of our customers and employees. The basis of our collaboration is that shared passion. Thanks to the passion of our customers in particular, I was able to move up the ranks in the company, starting from my initial job as a technician.

- Corporate Data

-

- Company name: AS Co., Ltd.

- Address: 1-18-26 Tsutsumi-dori, Sumida-ku, Tokyo 131-0034

- Representative: Hayakawa Masamitsu, Representative Director

- Business: planning, manufacture, and sales of vibration proofing, vibration damping, base isolation devices, shock prevention devices, soundproofing devices, and machinery and tools for air spring applications; planning, manufacture, and sales of labor-saving apparatus, machinery, and tools; measurement and analysis of vibrations and noise; other business associated with the above

- Capitalization: ¥85 million

- Employees: 70

- Website: http://www.a-sys.co.jp/

(Originally written in Japanese by Tsuda Hiroshi and Konno Ayaka. Photographs by Kagioka Ryūmon.)

earthquake Advanced System AS base isolation based isolator Hayakawa Masamitsu vibration-proofing Air Spring soundproofing environmental pollution National Museum of Western Art in Tokyo TCR base isolator