Kōno Seisakusho: World’s Thinnest Needles Bring Surgical Revolution

Economy Science Technology- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Thin Enough to Suture Blood Vessels

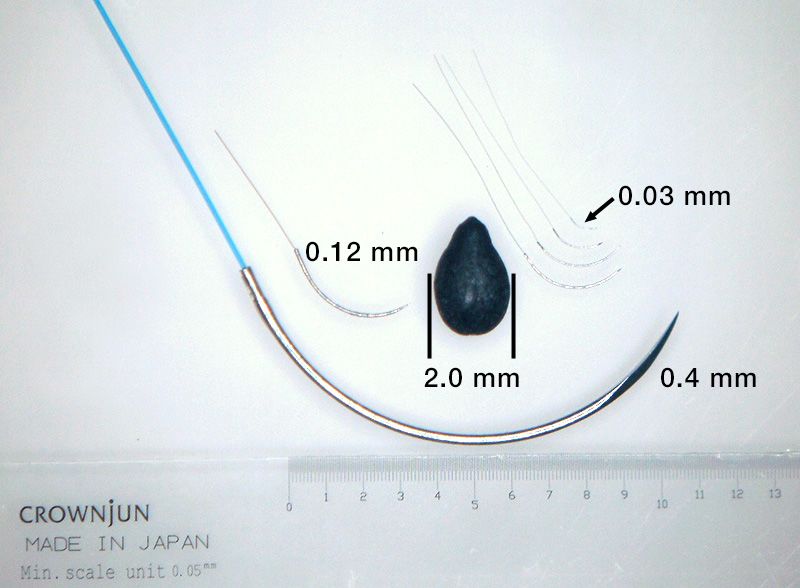

Needles for microsurgery compared with a sesame seed. (Photo courtesy of Kōno Seisakusho)

Needles for microsurgery compared with a sesame seed. (Photo courtesy of Kōno Seisakusho)

The world’s thinnest surgical needles have a diameter of 0.03 millimeters and are just 0.8 mm long. And the thread they pull is so fine, at 0.012 mm in diameter, that it is invisible to the naked eye. The development of these “Crown Jun” needles by Kōno Seisakusho, a small Japanese manufacturer, has revolutionized some fields of medicine, notably regenerative surgery, by making it possible to suture blood vessels, lymph vessels, and nerves less than 0.5 mm thick—procedures that had previously been considered impossible. These needles have also proved their utility in other types of surgery, such as reattachment of an infant’s severed finger.

In the field of microsurgery (surgery conducted using microscopes), needles with a diameter of 0.1 mm were previously standard. It was difficult to conduct sutures or other procedures on tissues with dimensions under 0.5 mm using such needles. But now that 0.03 mm needles have become available, highly skilled surgeons can perform “super-microsurgery”—procedures such as connecting blood vessels that are only 0.1 mm thick.

Overcoming Various Hurdles

The development of the 0.03 mm needle was completed in 2004 after three years of work. Kōno Jun’ichi, president of Kōno Seisakusho recalls, “Back then, people involved in medicine generally said there was no need for surgical needles that thin, and there were no manufacturers with the technology to produce them.” But one doctor at a university hospital asked Kōno if it would be possible to make thinner needles, and in response Kōno’s firm started working toward the 0.03 mm goal.

The undertaking proved extremely difficult. Surgical needles are made of a special type of stainless steel. The material is stretched and cut, one end is thinned to a point and bent, and the point is sharpened. But with such a small diameter, the metal material becomes limp, like cotton fiber. Each individual needle must be produced manually by a skilled worker using a microscope. Kōno Seisakusho developed its own tools and machinery especially for this purpose.

Another hurdle was finding a way to attach suture thread to the ultra-thin needle. In the case of regular surgical needles, a hole for the thread is opened at one end with a drill or laser beam. But there is no drill bit fine enough to open a hole in a 0.03 mm needle, and a laser beam causes the metal to melt. Kōno’s firm came up with a method based on a traditional technique: splitting the base of the needle into two prongs and squeezing the thread between them.

An Imperial Visit to an Award-Winning Small Firm

Kōno Seisakusho was founded in 1949 as a manufacturer of parts like needles for measuring devices. In the mid-1960s the firm shifted to the field of medical devices. Since then it has developed and produced threaded surgical needles of various specifications. It drew attention especially for its pioneering development of microsurgery needles, winning recognition from the Small and Medium Enterprise Agency in 2008 as one of Japan’s top 300 manufacturing ventures and receiving the Prime Minister’s Prize, the top honor at the Monozukuri Nippon Grand Awards (promoting excellence in the production of goods), in 2009. The following year, Emperor Akihito visited the firm’s headquarters plant.

Kōno Seisakusho President Kōno Jun’ichi. (© Kodera Kei)

Kōno Seisakusho President Kōno Jun’ichi. (© Kodera Kei)

Japan’s domestic market for surgical needles is on the order of ¥25 billion a year. About 10 companies, Japanese and foreign, are active in this field. Kōno Seisakusho currently produces around 10,000 types of needles, supplying them to general hospitals around the country. As President Kōno explains, his firm’s distinctive strength lies in its ability to produce many different items in small quantities, something big manufacturers cannot do. He notes that the firm handles everything from marketing to planning, design, development, and production in-house, adding that it also builds most of its own manufacturing devices.

Surgical needles account for about 80% of Kōno Seisakusho’s sales. Ultra-thin needles and other handcrafted items are produced at the firm’s headquarters plant in Ichikawa, Chiba Prefecture, while mass-produced items are made at its Tsukuba Plant, located in Jōsō, Ibaraki Prefecture. At the headquarters plant, where production involves precision work requiring great concentration, over half of the employees are women, many of whom commute to work by bicycle after dropping their children off at nurseries or kindergartens. They work in a quiet environment very different from a factory floor.

Developing International Sales

Since needles thinner than 0.05 mm are a niche product category, the scope for domestic sales is limited, but advances in organ-transplant techniques and increased use of regenerative medicine can be expected to lead to growth in demand for these needles. Meanwhile, the microsurgery market is expanding as medical treatment becomes more sophisticated, both in advanced countries and in the emerging countries of Asia. So Kōno Seisakusho is working to broaden its international sales channels.

The company is already hosting a stream of visitors from Thailand, Vietnam, China, and other Asian countries—all with markets that can be expected to grow. It set up an office in China in 2012 and is pursuing prospects for global expansion. The firm is getting ideas for new products from hospitals overseas as well as within Japan, and it is considering the possibility of conducting product-development activities in China. President Kōno is enthusiastic about his company’s unique technologies and confident in the potential of its Crown Jun surgical needles.

(Originally written in Japanese by Harada Kazuyoshi of Nippon.com and published on September 9, 2015. Banner photo: Attaching a suture thread to an ultra-thin surgical needle. © Kodera Kei.)

Corporate Data

Company name: Kōno Seisakusho Co., Ltd.

Head office: 2-11-10 Soya, Ichikawa, Chiba Prefecture, 272-0832

Representative: Kōno Jun’ichi, President

Business: Integrated handling of design, development, manufacture, and sales of medical devices

Employees: 161, including sales subsidiary (April 2015)

Website: http://www.konoseisakusho.jp/en/index.html