The Road to Hit Products by Kitamura Mori

Small Firms, World-Class Kitchenware

Economy Lifestyle- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Today Japanese market shelves are home to a surprising number of products marketed by small, virtually unknown companies that are selling as well as competing offerings from high-profile manufacturers. Vermicular cast-iron pots and the Multispeed Mixer food processor—popular kitchenware products from previously no-name firms—are two such examples.

Perhaps surprisingly, underpricing was not the key to their success. In fact, both products enjoy their enormous popularity despite sporting hefty price tags.

Products Worth Waiting For

Vermicular enameled cast-iron ware comes in seven pearl-tone colors.

Vermicular enameled cast-iron ware comes in seven pearl-tone colors.

The Vermicular enameled cast-iron pot retails for ¥25,200. Despite the steep price tag, orders started pouring in even before it went on sale in 2010. Today, two years later, the boom shows no signs of abating. Demand continues to outstrip production, and customers today must wait fully 15 months to receive their order.

In Japan, Le Creuset of France enjoys a solid reputation for its enameled cast-iron cookware. The French pots cost between ¥20,000 and ¥30,000. The colors are eye-catching, and the attractive cookware is a sure-fire way to impress guests.

Why would a person choose Vermicular over Le Creuset, when both cost about the same and Le Creuset’s name carries so much weight? Aichi Dobby Ltd., the company that manufactures Vermicular, is a small firm in Nagoya that produces industrial equipment parts. Vermicular is the first product the company designed and marketed on its own. Mention of “Aichi Dobby” would only be met with a blank stare. But mention of the arrival of a Vermicular pot, however, is guaranteed to impress.

How do Vermicular and Le Creuset cookware differ?

Quality enameled cast-iron pots are designed to be airtight. The heavy lid prevents the natural juices of the ingredients from escaping, and the ingredients cook to tender perfection with a minimum of water added.

Vermicular is said to be more than 10 times more airtight than Le Creuset cookware. The pot body and lid are built to fit perfectly. When I visited Aichi Dobby, I got a firsthand look at the care taken to achieve this: workers spent a full 20 minutes checking the fit of each and every pot.

Vermicular is produced entirely in Aichi Dobby’s facilities. Shaping of the lid (left) and enameling (right).

Vermicular is produced entirely in Aichi Dobby’s facilities. Shaping of the lid (left) and enameling (right).

Seeing Is Believing

Ingredients are placed in the pot and heated (left). An hour later, the vegetables’ natural juices have formed a delicious soup (center). Add the curry roux, cook the mixture briefly to thicken the sauce, and your seafood curry is ready to serve.

Ingredients are placed in the pot and heated (left). An hour later, the vegetables’ natural juices have formed a delicious soup (center). Add the curry roux, cook the mixture briefly to thicken the sauce, and your seafood curry is ready to serve.

What is the advantage of a pot this airtight? The answer is a cooking process that requires no added water or broth—something not possible with Le Creuset cookware. To see for myself the significance of this, I decided to make a pot of curry in a Vermicular pot. The directions were simple: First, place seafood and vegetables in the pot. Second, replace the lid and simmer for one hour. Sixty minutes later, the pot is filled with the natural juices from the vegetables, creating the soup into which the curry roux can be added. There is no need for any added water.

I do a fair amount of cooking, and until I tried this pot, I was convinced the key to a good curry was the inclusion of a special ingredient to give the dish a subtle but defining flavor. I could not believe the Vermicular pot of curry tasted so good despite being made out of nothing more than vegetables, seafood, and roux. It was clear that not adding water was the way to bring out the full flavors of the ingredients. The result went beyond my expectations.

Word of the Vermicular wonder spread like wildfire among food and cooking aficionados after the pot hit the market. Some people said it was great for stewing; others said it was perfect for basting meat. Aichi Dobby is a small company with a limited advertising budget, and its early marketing efforts went little beyond posting some users’ comments and recipes on its website. The impact, however, was amazing, leading to the pot’s current popularity. The company even received messages from people who used to hate spending time in the kitchen but had taken up cooking after purchasing a pot and from parents happy to have found a way to get their children to enjoy the vegetables on their plates.

Quality Assurance

Some may wonder why Aichi Dobby did not subcontract work to other companies in the face of such a backlog of orders. The firm has not outsourced any of its production, though, and has no plans to do so in the future. Hijikata Kunihiro, the company’s president, and his brother Tomoharu, the senior managing director, both feel strongly that production work must be carried out exclusively within its small Nagoya plant.

The reason for this, however, is not to safeguard the secrets of production. It is because they believe this is the only way to ensure the intricate balance required by the pot’s design. The production process includes casting of the pots and lids, machining of the seams, and enameling. It took Aichi Dobby a full year to develop the process and needed technologies, and the company remains the only firm in Japan that can handle the entire task. The Hijikata brothers say that their company must control all three stages of production in order to maintain the pot’s exceptional airtight standards. Though production was stepped up to 2,000 pieces a month, there is still a 15-month backlog of orders, and more than 30,000 customers are now waiting for a pot.

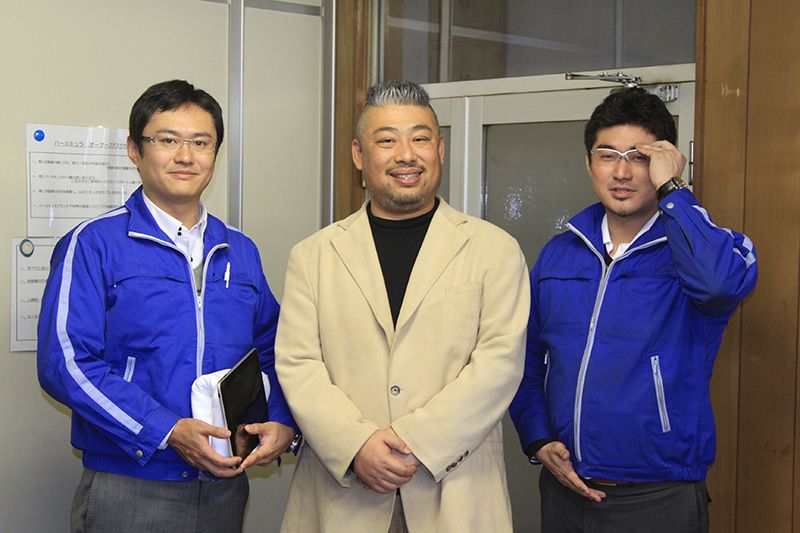

Hijikata Kunihiro and Tomoharu, the two brothers who run the 55-person firm, created a pot now regarded as the best in the world.

Hijikata Kunihiro and Tomoharu, the two brothers who run the 55-person firm, created a pot now regarded as the best in the world.

“Though we’re a small firm, we wanted to try our hand at something new.” The brothers who run the company and designed the pot talk about how they came to embark on the project. “We hit upon the idea of a cast-iron pot because it was a way to put our know-how to use.” The fruit of their efforts was a product whose features are out of the reach of the big-name manufacturers.

The Internet and online reviews proved to be a powerful tool for publicizing Vermicular. But sales have stayed strong because the product itself has something competing items do not. Quality products are ultimately discovered, something the Japanese market today certainly bears out—and something exemplified by the second product discussed in this article, another item with many excellent features that consumers found and made their own favorite.

Going Beyond Consumer Expectations

The Multispeed Mixer has a chic design that gives it the look of a stylish coffee maker.

The Multispeed Mixer has a chic design that gives it the look of a stylish coffee maker.

The Multispeed Mixer Master Cut was designed and produced by Yamamoto Electric Corp., a company based in the city of Sukagawa, Fukushima Prefecture. This food processor went on sale in 2010 for ¥12,000.

Similar food processors from major appliance makers can be purchased for as little as ¥8,000, but the Multispeed Mixer has nonetheless secured an increasingly large market share in major online shops since 2011. It now enjoys a definite lead over competing products from major manufacturers.

Food processors are not a fixture in Japanese kitchens. The machines on the market are noisy, a definite disadvantage in apartment buildings and houses built closely together. But they also lack settings for coarseness and fineness. When chopping onions, for example, it is easy to overprocess them and turn them into juice. Washing the devices is also difficult because of their many small parts.

How does the Multispeed Mixer compare?

The inside of the Multispeed Mixer’s bowl. The structure is simple and the parts are very easy to wash. “We were exacting about everything, right down to the color of the blade,” says a company spokesperson.

The inside of the Multispeed Mixer’s bowl. The structure is simple and the parts are very easy to wash. “We were exacting about everything, right down to the color of the blade,” says a company spokesperson.

First, this food processor has aesthetic appeal. With its stainless steel exterior and its bold color scheme of deep red and black, it looks as attractive as a chic coffee maker. This is an object people would want to have in their kitchen.

The Multispeed Mixer’s motor is quiet, producing little more than a low hum—a definite point in its favor. The processor’s speed dial does not have the conventional slow, medium, and fast settings but is a stepless control, allowing the user to finely control the machine’s speed.

The importance of this stepless control dial cannot be overstated. Meat can be ground to just the right consistency. Until now, only professional models had this feature; the Multispeed Mixer is the first mass-market appliance to offer it.

Meat is ground in just a few seconds. Since users can control the speed perfectly with the stepless dial, they no longer have to worry about overprocessing.

Meat is ground in just a few seconds. Since users can control the speed perfectly with the stepless dial, they no longer have to worry about overprocessing.

Food processor bowls are generally made out of glass, but the Multispeed Mixer has a stainless steel bowl, another big advantage. Stainless steel is lighter than glass, making it easier to transfer ingredients to another bowl or pot. Cleaning the machine is a breeze, because the bowl and other parts are easy to wash and unbreakable. The bowl is round and the spindle to which the blade attaches has few ridges. The simply designed, easy-to-wash blade is another strong point for the food processor.

The Priorities of a Motor Maker

Very few people have heard of Yamamoto Electric, the company that produces and markets the Multispeed Mixer. The firm’s main line of business is the production of motors for vacuum cleaners and automobiles; its products can be found in many vacuums on the global market and in Japanese and German cars. Yamamoto Electric developed its food processor 20 years ago, but until recently its marketing efforts were limited to demonstration sales in cooking classes and other places, and sales were limited. The mixer’s popularity skyrocketed after the firm revamped the design and remarketed it.

One thing that the company refused to change when redesigning the model was the direct link between the motor and the blade spindle. Other companies connect the motor and spindle with a belt, but Yamamoto Electric links the two directly. This ensures that power is not wasted and minimizes noise. The settings for speed, meanwhile, are another important point. Food can thus be chopped as finely or coarsely as desired. This machine motor production firm was remarkably successful finding solutions that eluded major appliance manufacturers.

Cooking Made Easy and Fun

The Multispeed Mixer achieved its success by addressing the complaints users had with conventional models—and by being fun to use at the same time. The device cuts down on preparation time by handling tiresome ingredient preparation tasks. It also gets cooks’ creative juices flowing, enticing them to make even challenging dishes like meringues on their day off.

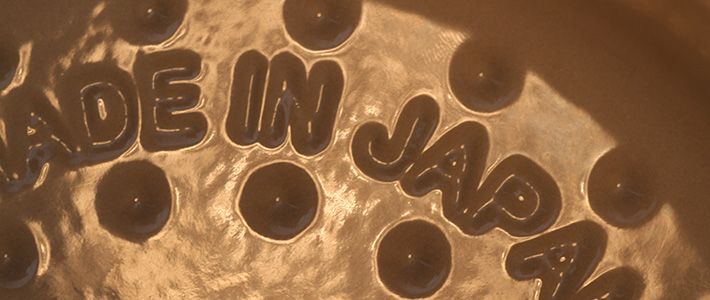

Aichi Dobby and Yamamoto Electric are both considering marketing their products overseas, and it may not be long before the Vermicular pot and the Multispeed Mixer are fixtures in kitchens overseas. Aichi Dobby may have been prescient in its decision to engrave “Made in Japan” in big letters on the inside of the lid starting with the first batch to come off the line two years ago.

(Originally written in Japanese. Photographs by Kawai Satoshi.)

manufacturing ingredients Kitamura Mori Aichi Dobby Vermicular Le Creuset Cooking cuisine kitchenware Multispeed Mixer food processor enamelware Yamamoto Electric kitchen