Spotlight on Hamadōri: the Fukushima Innovation Coast Framework

The Creative Robot Contest for Decommissioning

Technology Education- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Along the Hamadōri coastline region of Fukushima Prefecture, people refer to the work of dismantling the Fukushima Daiichi Nuclear Power Station’s reactors as the primary focus of the national project known as the “Fukushima Innovation Coast Initiative.” But even now, 12 years since work began, the decommissioning of the station (straddling the towns of Ōkuma and Futaba) can hardly be said to be progressing smoothly.

The release of treated water into the open sea—one of the persistent problems associated with the damaged nuclear power plant—was scheduled to enter into the operational phase during the spring and summer of 2023, but the situation remains in a state of flux. The tanks of tritium-contaminated water that continue to accumulate at the site are causing delays in other tasks being carried out there. The COVID-19 pandemic also had a negative impact on the progress of the work. Thus, the start of the most difficult part of the decommissioning effort, the retrieval of fuel debris, has been postponed to the latter half of the 2023 fiscal year (April 2023 to the following March) from its original start date in the 2021 fiscal year.

As there remains no end in sight for the decommissioning effort, it is shrouded in a persistent gloominess. However, a glimmer of hope has emerged as a result of the Creative Robot Contest for Decommissioning, which is sponsored by the Naraha Center for Remote Control Technology Development (NARREC), itself established by the Japan Atomic Energy Agency. This event, which is the embodiment of NARREC’s slogan, “Shifting focus from a disaster site to a ‘challenge’ site,” provides a glimpse into the future that will be opened up by the eventual decommissioning of the facility.

Fukushima Daiichi as it appeared in September 2022. Units 3 and 4 can be seen behind the rows of treated water tanks. (© Nippon.com)

Construction work on water discharge shafts, seen here, has been delayed. (© Nippon.com)

Remote Technologies Essential to Decommissioning

The town of Naraha is the site of the National Training Center J-Village, which served as the base of operations for the cleanup efforts immediately following the Fukushima Daiichi disaster. It is the location of Fukushima Daini Nuclear Power Station, where decommissioning efforts are also ongoing. NARREC is located approximately 1 kilometer to the west of J-Village.

The decommissioning of Fukushima Daiichi is completely uncharted territory. Due to the high levels of radioactivity, remote-controlled robot technologies are essential to all the work, from identifying the conditions within the nuclear reactor to retrieving the nuclear fuel debris. This requires careful planning and repeated trial runs. With its research management and testing facilities, NARREC handles these trial runs.

Its research management facility is equipped with a virtual reality system that is able to re-create the interior of the reactor building. This allows researchers to examine various plans suggested for the decommissioning of the power plant and to conduct repeated trials. When linked to a robot simulator, the system allows researchers to examine in detail various aspects of the effort, including the perspective from which any given camera is filming and whether material being carried by a robot will be able to pass through narrow hallways and stairways.

The Research Management Building as seen from the entrance to NARREC. (© Nippon.com)

The VR System, which realistically re-creates the interior of a nuclear reactor building.(© Nippon.com)

The testing facility is an enormous building measuring 40 meters in height and 80 by 60 meters along its sides. Its interior includes a testing area with an actual-size model of a nuclear reactor containment vessel, a water tank for robotic tests, a mock-up of a staircase, and an element test area with motion capture equipment.

While the organizations and companies involved in decommissioning tasks continue to carry out tests at the facility, the Creative Robot Contest for Decommissioning has been held at the same location each year in December.

The enormous testing building. (© Yamada Shinji)

The water tank used for robot testing can be seen in the center. The orange handrails seen on the left are part of the “mock staircase” that can be used to simulate a variety of types of staircases found within nuclear reactor buildings.(© Nippon.com)

Tough Competition

The Creative Robot Contest for Decommissioning was first held by NARREC in 2016 based on a proposal by educators at the National Institute of Technology, Fukushima College, located in the nearby coastal city of Iwaki. Fourteen teams from 12 specialized vocational high schools around the country participated in the seventh contest, held on December 10, 2022.

A female student from Fukushima’s National Institute of Technology reads the Participants’ Oath at the Opening Ceremony. (© Yamada Shinji)

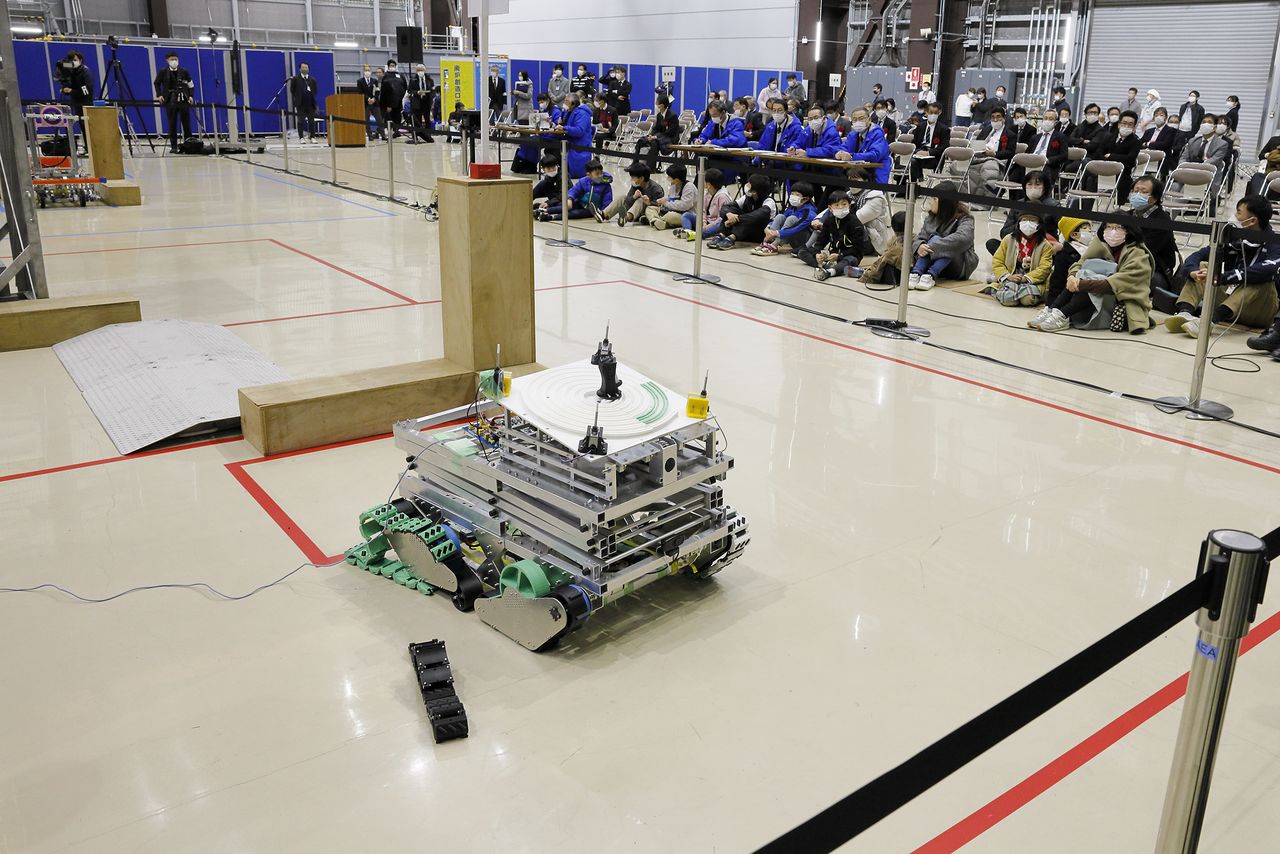

Each team consists of three students and one teacher who serves as advisor. They had to perform a wall decontamination task in which they competed to see how much of a piece of imitation vellum attached high on a wall could be accurately colored in (which simulates surface decontamination work) within the 10-minute time limit.

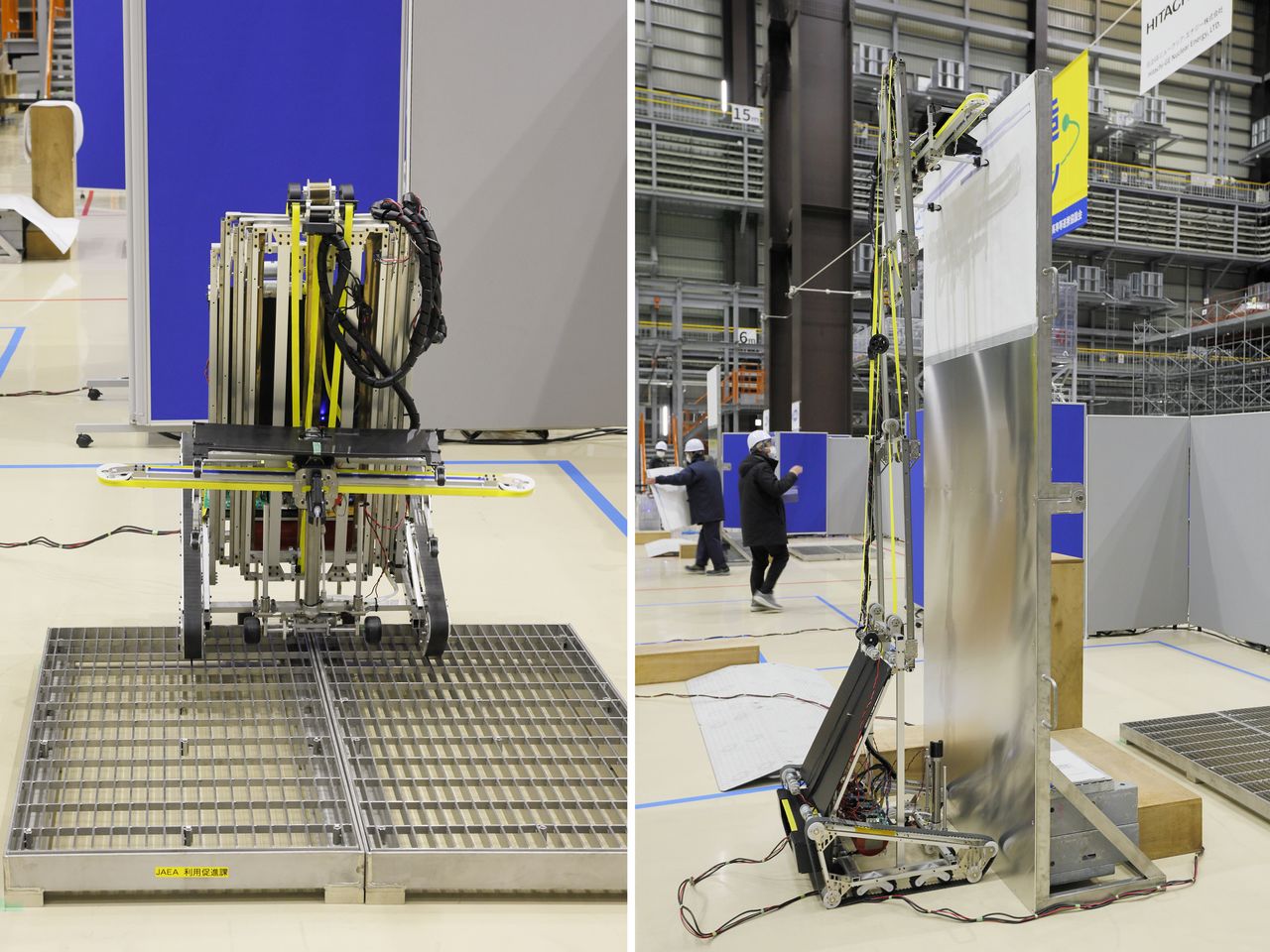

This task is similar to those that are performed within nuclear reactors, in that the robot’s movements cannot be directly observed as they are operated remotely from an operation area on the other side of a wall. The task involves maneuvering the robot down a narrow hallway strewn with debris within a nuclear reactor building. The robots must measure within 95 centimeters in both length and width and 100 centimeters in height at the start of the task, without any robotic arms or other apparatus extended. The course includes twists and turns, as well as slopes and gratings (scaffolding consisting of iron grating) that must be navigated successfully. Once a wall measuring 2.7 meters in height is reached, the robot’s arm is extended upward and the mock decommissioning task is begun.

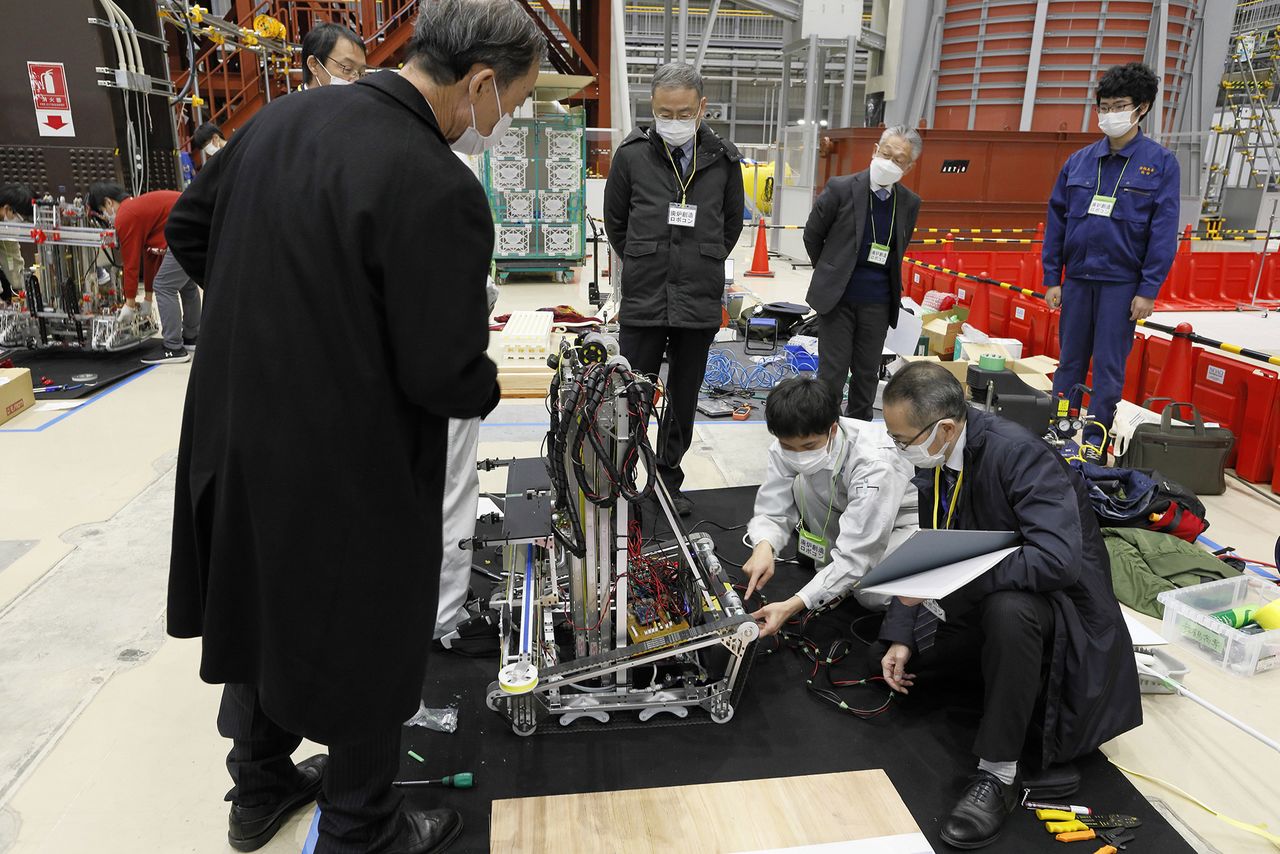

On the day before the contest each team conducted two test runs, but most teams were unable to even reach the wall. Many could be heard expressing their frustration at the inability of their robot’s camera, for example, to accurately judge distance or at how unexpectedly slippery the floor was. One team’s robot was unable to clear the iron grating just 95 millimeters in height. They could be seen hurrying to repair and adjust their equipment before the actual contest began.

Left: The robot of the National Institute of Technology, Maizuru College (Kyoto) team clears the grating obstacle on a test run. Right: A robot that has reached the decontamination area extends its ladder-like arm to raise a pen used to color in a piece of imitation vellum in a way that is similar to actual surface decontamination work. (© Yamada Shinji)

The operation area is walled off by a partition. Operators depend on data obtained by the robot’s camera and other sensors to operate the device. (© Yamada Shinji)

Once the competitors return to a behind-the-scenes pit stop area after their trial runs, they throw themselves into making repairs and adjustments to their robots. (© Yamada Shinji)

A Visit to Fukushima Daiichi

Suzuki Shigekazu, who teaches at the National Institute of Technology, Fukushima College, and supervised the progress of the competition, looked on with a smile on his face. “Seems they are having some trouble,” he said. “The competition simulates the actual conditions of the decommissioning work, and so it is supposed to be difficult,” he added. “One of the unavoidable conditions of remote operation within the Fukushima Daiichi Nuclear Power Plant is slippery floors. In actuality, the floors may be even slipperier. To give the competitors some sense of this and other actual conditions, they all went on a tour of the actual site in the summer.”

The task for each year’s Creative Robot Contest for Decommissioning is announced in mid-April. Teams submit an “idea sheet,” and the teams that pass the initial document screening start developing their robots in mid-July. In August all participants meet to tour the NARREC facility, where they see the competition venue and decommissioning robots manufactured by corporations. It is at this time that they also tour Fukushima Daiichi itself.

Students visiting Fukushima Daiichi Nuclear Power Plant during the Contest’s “Summer School.” (Courtesy the National Institute of Technology, Fukushima College)

“The Creative Robot Contest for Decommissioning is a personnel training program,” explained Suzuki. “With the wide variety of information available to the public—and not all of it necessarily accurate—there are many students who believe that Fukushima Daiichi cannot be approached without first donning a complete set of protective gear. But in fact it is possible to come very close to the nuclear reactor building in normal street clothes. Having the students see for themselves the progress being made in the decommissioning work and in the efforts to rebuild the Fukushima region, as well as having them participate in the actual development of new technologies, are among the most important goals of this contest.”

Suzuki Shigekazu holds a PhD in engineering and is an associate professor at the National Institute of Technology, Fukushima College. (© Yamada Shinji)

Even during breaks between test runs, the judges examine the robots. (© Yamada Shinji)

Frustration Propels Growth

On the day of the contest, only two teams were prepared to take on the decommissioning task. Most of the teams had run into trouble when trying to get their robots to maneuver over the iron grating. There were teams that gave up at the start of the competition due to the difficulty of successfully accomplishing this via remote control.

But even the teams that dropped out were given the chance to demonstrate the ideas and technologies, such as the movements of the robotic arm, that they had come up with.

The robot entered by the team from the National Institute of Technology, Ichinoseki College (Iwate), suffered a broken caterpillar track shortly after the start of its run. The team won a special award for the ingenuity of its pen that is able to move in a spiral motion. (© Yamada Shinji)

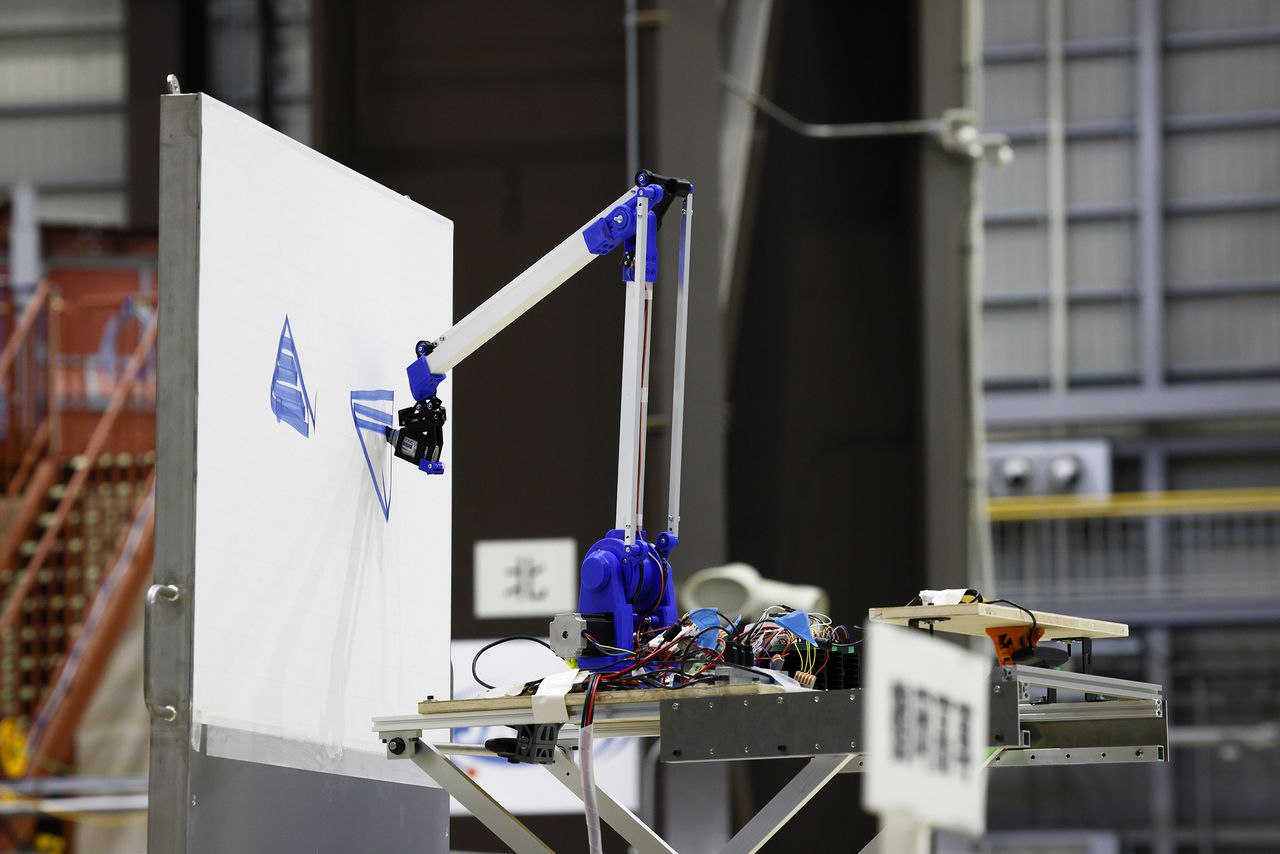

The National Institute of Technology, Tsuruoka College (Yamagata), team, which won the Director of the National Organization of Vocational High Schools Award (the “Idea Award”), shows off the sophisticated movements its robot’s arm is capable of. (© Yamada Shinji)

The National Institute of Technology, Oyama College (Tochigi), team was awarded the Minister of Education, Culture, Sports, Science, and Technology Award, equivalent to the grand prize, making this the second consecutive time this team has taken top honors in the contest. Not only did their robot successfully maneuver the course, they also had time to color in the vellum a second time to ensure that they covered any spots missed during their first pass. The Fukushima Governor’s Award, equivalent to the outstanding performance award, was given to the team from the National Institute of Technology, Maizuru College, as they were also able to complete the entire decommissioning task. Their robot was able to easily clear the iron grating due to the fact that it was equipped with air cylinders in front and back that could lift the robot up and over the obstacle.

Suzuki summed up the contest as follows: “Once these people go out into the world as engineers, they will be met with even more difficult tests. Hopefully they will use the hardships they had to overcome in this contest as a springboard that propels them to develop robots that can play a role in the decommissioning of Fukushima Daiichi Nuclear Power Station.”

The National Institute of Technology, Oyama College, team, which won the grand prize, and its robot. (© Yamada Shinji)

The Oyama College team’s robot coloring in the imitation vellum. The team won the competition handily as its robot’s capabilities far surpassed those of its competitors. (© Yamada Shinji)

After the contest, Satō Kengo of the National Institute of Technology, Sendai, team—which was awarded a special prize—said in no uncertain terms that he wanted to work on decommissioning robots in the future. Originally from the city of Minamisōma in Fukushima Prefecture, he remembers what it was like to live as a disaster refugee as the earthquake and tsunami disaster struck shortly before he entered elementary school. He decided to become an engineer so that he could do work for the benefit of his hometown, which has additionally suffered from many years of damage to its reputation as a result of the nuclear disaster.

“In the summer, during our visit to Fukushima Daiichi, I gained an understanding of just how daunting the task is, as I could see how difficult it is to maneuver a robot inside the nuclear reactor building,” he reflected. “Through my experience in this contest I learned the importance of planning and of being able to handle problems and setbacks. I want to utilize this experience in the future by contributing to the decommissioning effort.”

Contest participant Satō Kengo, who was disappointed in spite of having won a special prize. (© Yamada Shinji)

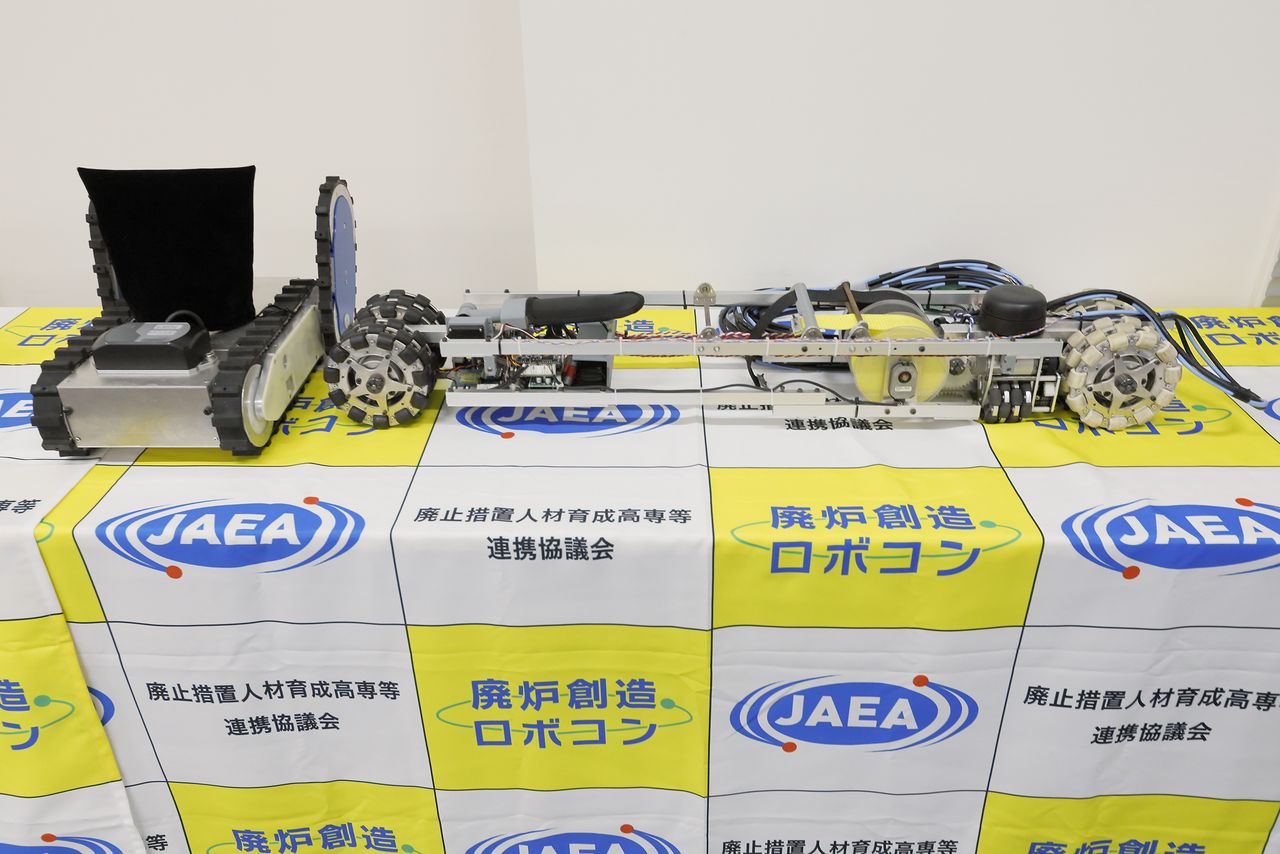

Using an idea generated by the National Institute of Technology, Fukushima College, team, which won the minister’s award in the 2020 contest, a Tokyo corporation known as Atox—which is concerned with the maintenance and management of nuclear power plants—developed a small data-gathering robot. In this and other ways, the Creative Robot Contest for Decommissioning is contributing to the production of real-world results.

The decommissioning work is expected to continue for the next thirty years or so. Thus, the contest is also helping to train a new generation of promising young people who will carry on the work for many years to come.

On the right is the robot, called “Mexicali,” designed and built by the Institute of Technology, Fukushima College team that won the fifth Creative Robot Contest for Decommissioning. On the left is the small-sized data-gathering robot developed in cooperation with the Atox corporation. (© Yamada Shinji)

(Banner photo: Members of the National Institute of Technology, Fukushima College, team preparing their robot for the contest. © Nippon.com.)