Cleaning Up Aquaculture: Joint Project Takes on Plastic Waste from Oyster Farming in Hiroshima Bay

Newsfrom Japan

Environment Lifestyle- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Targeting “Zero Marine Waste”

To reduce plastic waste in the Seto Inland Sea, the four prefectures of Hiroshima, Okayama, Ehime, and Kagawa launched the Setouchi Oceans X project in partnership with the Nippon Foundation in December 2020. Each year, an estimated 388 tons of waste is generated in the coastal waters of these prefectures. Public agencies collect about 302 tons of that. The Oceans X initiative aims to recover the remaining 86 tons while also establishing systems to prevent waste from being generated in the first place.

On July 5 this year, a large-scale cleanup effort took place in the four prefectures. Around 1,000 participants, including fishery workers and local residents, volunteered to collect approximately 26 tons of waste along beaches and riverbanks.

Cleanup efforts in Hiroshima (top); oversized floats that don’t fit into trash bags. (Courtesy Nippon Foundation)

At the cleanup site on the Arajiro Coast in Etajima, Hiroshima, large numbers of polystyrene floats, which are used for aquaculture rafts, were found washed ashore.

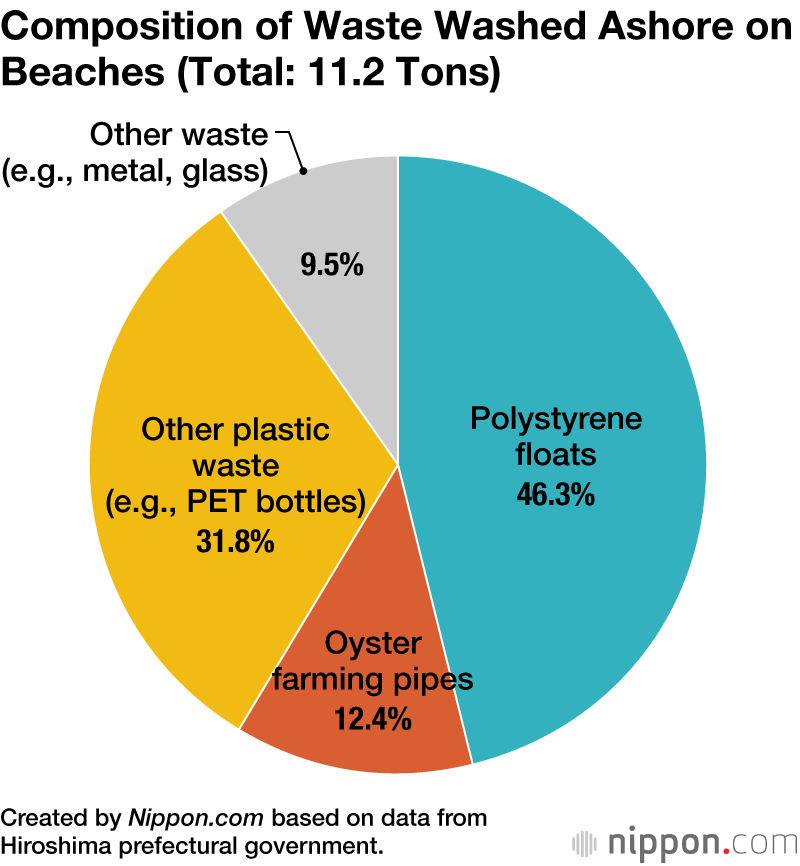

Hiroshima Prefecture has set a goal of eliminating all new plastic waste flowing into the Seto Inland Sea by 2050. However, the floats, which make up nearly half the weight of all beach litter, pose a significant challenge. Hiroshima Bay is the top oyster-producing area in Japan, using over 300,000 floats, which is more than anywhere else in the country. Entire floats and degraded fragments frequently scatter and accumulate in hard-to-reach coastal cliffs, making recovery extremely difficult.

Float waste washed ashore at Ujina Beach in Hiroshima (top); once broken down into microplastics, the impact on the ecosystem is severe. (© Nippon.com)

Prevention the First Step

With limits to what human resources alone can achieve in cleanup efforts, the most effective approach is to prevent waste from entering the sea in the first place. With this in mind, Oceans X has developed improved floats and protective covers with enhanced durability.

The two floats on the right are newly developed high-density models with protective black covers. The white one in the center is the float body that goes inside the cover. Between these is the standard model. In the front left is a discarded float found on the shore. (© Nippon.com)

Conventional floats often shrink under water pressure and slip out of the bands used to secure them to aquaculture rafts. The newly reinforced floats retain the same dimensions but are 1.2 times denser, making them more resistant to compression underwater. Meanwhile, the protective covers, which help prevent damage from ultraviolet rays and other wear, are three times more tear-resistant compared to standard lightweight products. Used together, these upgrades are expected to extend the floats’ service life from the current average of three years to between five and eight years.

A light buoy raft equipped with floats, visible above the water. The weight of oysters on aquaculture rafts causes floats to submerge and makes them more susceptible to compression. (© Nippon.com)

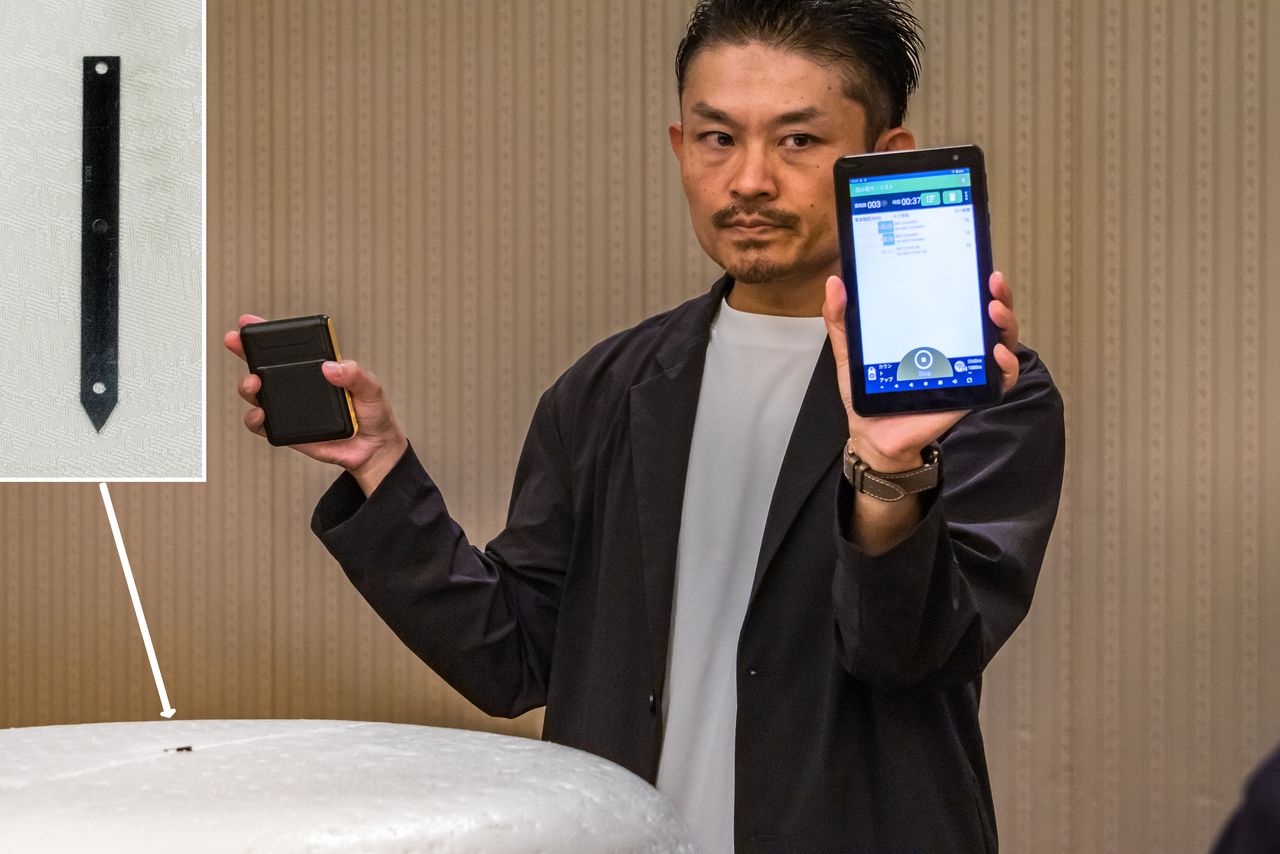

A new management system using radio frequency identification technology has also been introduced. By embedding metal tags into the floats, their information can be read instantly and simultaneously by a scanner. This enables identification of the owner, tracking of the source of discarded waste, and monitoring to prevent overuse or neglect of aging equipment.

Scanning a float embedded with an IC tag using a specialized reader displays information on the device. (© Nippon.com)

Starting in July, a pilot project has been launched with the cooperation of oyster farmers in Hiroshima Prefecture. A total of 1,000 new floats will be gradually installed on 30 aquaculture rafts, with their durability and performance monitored. The goal is to move toward full implementation after a year.

Some floats without protective covers were seen at the aquaculture site. (© Nippon.com)

On July 15, the media were invited to observe the installation of the new floats at an oyster farm in Hiroshima Bay. Yoneda Terutaka, the head of the Hiroshima Fishery Cooperative, commented, “Unless we fishers change our mindset, consumers won’t support us. We’re committed to working our hardest to pass on the delicious oysters of the Seto Inland Sea to future generations.” Unno Mitsuyuki, executive director of the Nippon Foundation, also expressed his hopes: “Marine debris is a global concern. We want this project to succeed so that it can be adopted in other regions facing similar issues.”

Replacing old floats with new models. Each raft uses a little over 30 floats. (© Nippon.com)

Will this initiative succeed in tackling the severe problem of marine waste that pollutes the Seto Inland Sea? The hope is that this effort will serve as a model for aquaculture communities both in Japan and around the world.

Yoneda Terutaka of the Hiroshima Fishery Cooperative (right) pledges to take on the mission of float waste reduction. (© Nippon.com)

(Originally written in Japanese. Banner photo: Oyster farmers replacing floats beneath their rafts. Photo taken on July 15 in Hiroshima. © Nippon.com.)