Yuki Precision: A Tradition of Craftsmanship That is Out of This World

Economy Technology Work- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

New Lease on Life

Japan is renowned for its industrial craftsmanship, a reputation built by the nation’s army of small and medium-sized manufacturers. However, more and more companies are in dire straits as factors like increased global competition and an aging and shrinking working population diminish the outlook for growth, forcing many firms to shutter their operations.

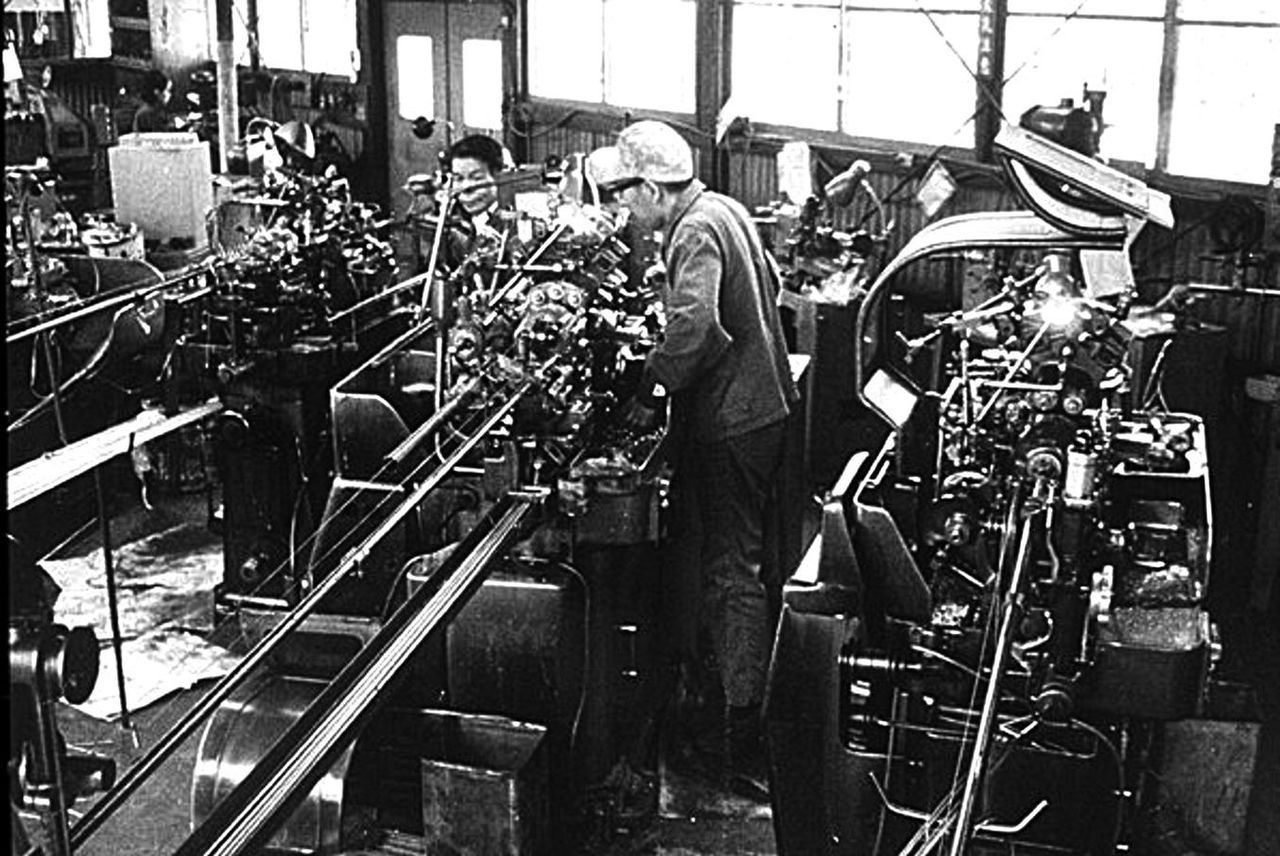

Kanagawa Prefecture-based Yuki Precision was one such manufacturer fighting to keep its head above water. Founded in 1950, it started out making screws at a small factory in Chigasaki. Leveraging its reputation for precision cutting, in the 1980s it began producing metal parts used in public telephones, only to watch demand dry up as cellular phones took off. Switching its focus to optical fibers, the firm chugged along until the crash of Japan’s IT bubble in 2001 put the fortunes of the business in peril again.

A worker operates a machine at Yuki Precision’s original factory. (© Yuki Precision)

It was under this cloud that current CEO Ōtsubo Masato joined the firm in 2006. The grandson of the founder and son of the second president, he brought business acumen that the company desperately needed. He had earned a master’s degree in mechanical engineering from the University of Tokyo and spent six years at leading Japanese manufacturer Incs (now Solize) before deciding to help the struggling family business dig its way out.

Looking back, Ōtsubo admits he underestimated the company’s troubles. “Business was booming at Incs when I was there,” he says. “I’d been part of the firm’s rapid growth and figured turning around a small metal crafter would be a piece of cake by comparison.” What Ōtsubo found, though, was a company riddled with debt.

Yuki Precision owed several times more than what it made in annual sales, meaning that no matter how many products it managed to get out the door revenue was siphoned off by repayments. The only recourse, Ōtsubo figured, was to make an all-out effort to procure new clients. And so started for him a period of long days with little sleep.

“The first step was to highlight our strong suits,” he explains. Next, he established a department providing R&D services. “After that, it was sell, sell, sell.”

Ōtsubo surveyed and interviewed customers, using the results to analyze the company’s strengths. Clients were clearly satisfied with the high quality of production, including the manufacturer’s ability to precisely machine parts down to the micron level, roughly one-tenth the breadth of a strand of hair. Such advanced techniques had been the backbone of the business from the start.

However, it took a new approach to R&D. In setting up the department, Ōtsubo drew on his experience, establishing the scope of the service to include not only the handling of orders but also design assistance, including working alongside clients and making proposals for products in line with their needs. Armed with his advanced engineering degree and knowhow from Incs, where as a new recruit he cut his teeth leading a major project, he was able to offer clients an unmatched level of expertise.

Employees hard at work at the company’s R&D department. (© Yuki Precision)

Breaking into Aerospace

With the survival of the company on the line, Ōtsubo threw himself into the task of luring new clients, relying on the firm’s core precision cutting technology and new “proposal-based” manufacturing approach extending from R&D to production. He oversaw each step in the process, from customizing sales pitches based on the individual needs of potential customers to finalizing orders.

He specifically set his sights on the aerospace industry, where he knew that traits like precision and quality were in high demand. “I dreamed of breaking into the market,” he says. Although the majority of the company’s business was with electronics makers, Ōtsubo was confident Yuki Precision could meet the industry’s exacting demand for safety and highly reliable, specialized parts.

Breaking into the demanding aerospace field tested employees, who bent over backward to fill even the most challenging orders. Every effort was made to promote the company, and in 2008 opportunity finally knocked. While participating in an international aerospace exhibition, the company’s display of machined parts caught the eye of the likes of JAXA, the Japan Aerospace Exploration Agency, for their level of precision and quality, leading to a long-term relationship with the organization.

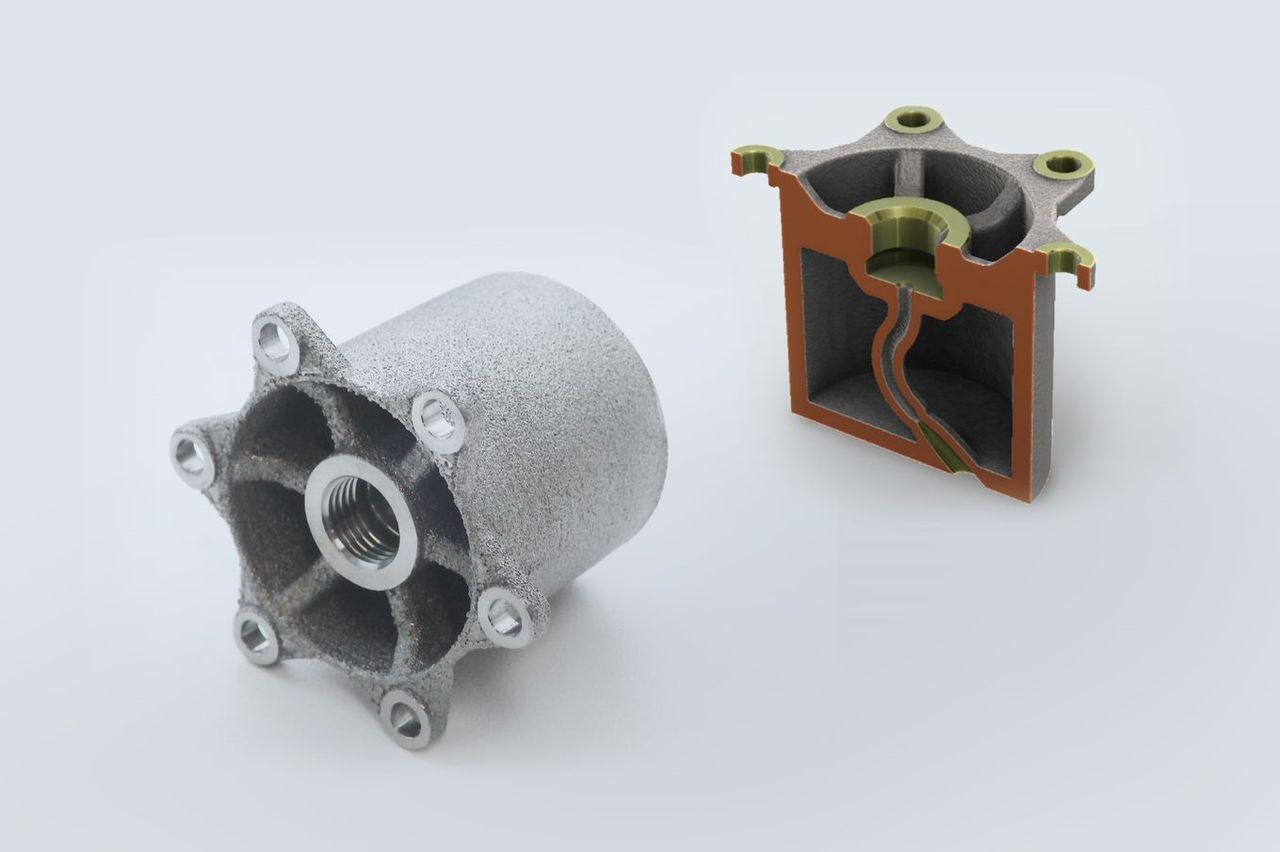

A specialty wire mesh alloy was one of the parts Yuki Precision displayed at the 2008 aerospace exhibition. (© Yuki Precision)

Things progressed rapidly from there. The company acquired JIS Q 9100 certification, a quality management system required by manufacturers in the aerospace industry in Japan for quality control in the aerospace industry, leading to an order for parts for aeronautical equipment from a major manufacturer. This was followed by Japanese small-satellite startup Axelspace commissioning structural components for one of its nanosatellites. Yuki Precision also had a hand in designing and manufacturing a satellite for Astroscale, a space venture focused on cleaning up orbiting debris. Building on this track record, the company has continued to garner a steady stream of new clients in the aerospace industry.

Titanium nozzles used in the unmanned probe Hayabusa 2. The parts were 3D printed and various elements precision machined. (© Yuki Precision)

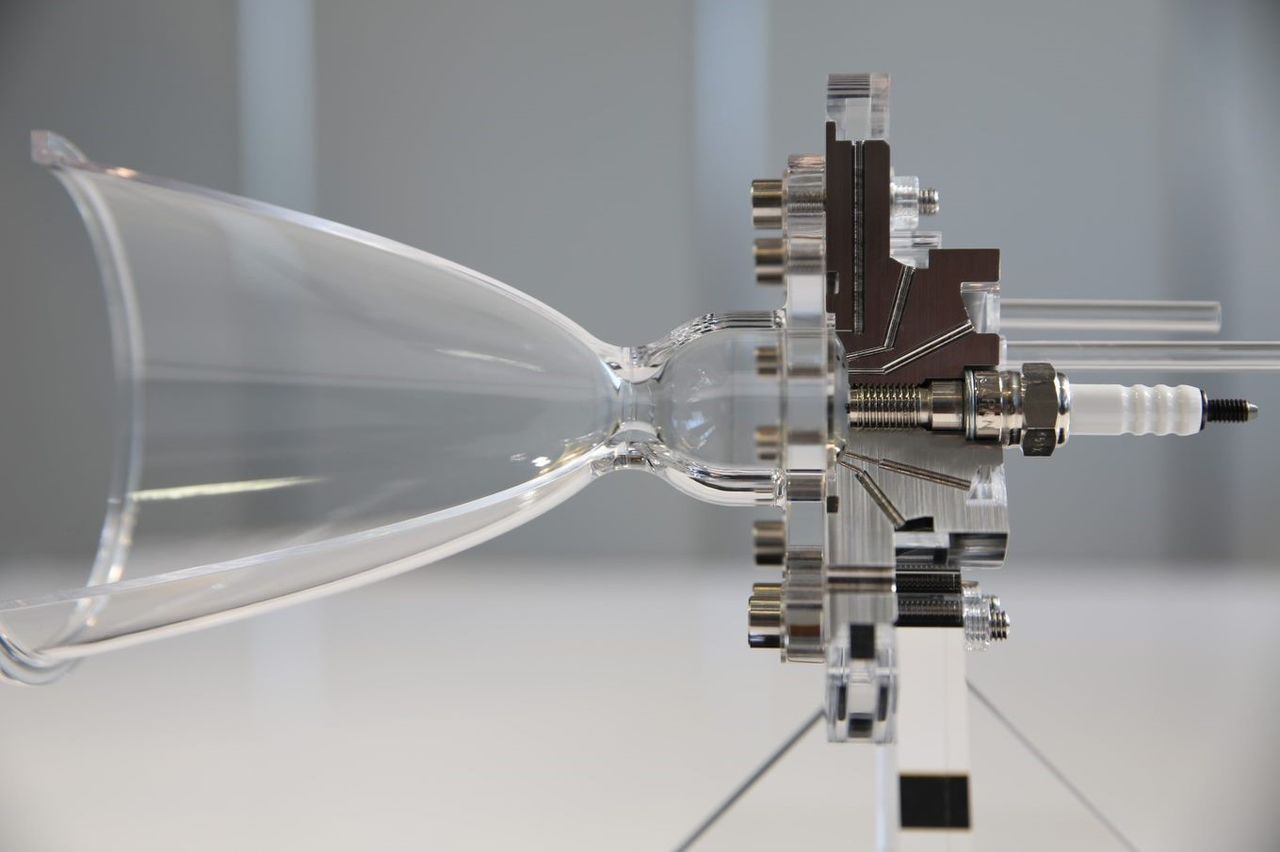

An injector for a two-stage liquid-propelled rocket engine manufactured by Yuki Precision. (© Yuki Precision)

In his first five years at Yuki Precision, Ōtsubo succeeded in diversifying the firm’s production base from electronic components to parts for aerospace equipment, increased its client portfolio by a factor of five, and boosted sales an average of 10% year on year. Although it took a decade to accomplish, the company is now on an even keel, having achieved a dramatic V-shape recovery.

Bolstered by its success, Yuki Precision has branched out into new ventures. In 2015, it opened a subsidiary in France. It also collaborates with a leading Japanese watchmaker, supplying precision parts for a line of mechanical watches equipped with tourbillion functions that improve the accuracy of the time pieces. In the audio realm, it has won acclaim for developing a high-end analog turntable.

The tourbillon Pura by Japanese watchmaker Asaoka Hajime. (© Yuki Precision)

Yukiseimitsu Audio’s AP-0 analog turntable. (© Yuki Precision)

Ōtsubo has even dipped his toes in artistic waters by collaborating with DJ and artist Tokui Nao on a work for Industrial JP, an audiovisual project combining music with images and sounds from machikōba—small-scale urban factories like Yuki Precision operates. In 2017, the work helped Industrial JP win bronze at the Cannes Lions International Festival of Creativity and Japan’s Good Design Gold Award, accolades that drew global attention to Japanese manufacturing craftsmanship.

Banding Together

Heading Yuki Precision’s turnaround, Ōtsubo experienced firsthand the difficult business landscape small manufacturers face. He points out that there are a lot of what he calls “limiting factors,” but insists that these are not insurmountable.

For instance, small and medium-sized manufacturers are limited in their abilities to employ business specialists. Casting about for ways to help firms address such restricting factors, Ōtsubo came up with the idea of forming a holdings company.

He looked to French multinational LVMH for inspiration, finding in it an approach that provides subsidiaries access to established business infrastructure while also respecting their individual traditions. He notes that most consumers consider major brands like Bulgari and Celine to be independent, although in reality they are part of the conglomerate. “The scale is totally different,” he admits, “but borrowing LVMH’s approach helps shine a light on struggling manufacturers that are making advanced products, helping them get back on a solid business footing by providing access to much-needed managerial resources.”

In 2017, Ōtsubo launched Yuki Holdings, structuring the conglomerate to provide subsidiaries access to a broad range of resources from business strategy, financing, and planning to public relations, recruitment, IT, and R&D.

One of the main ambitions of Yuki Holdings is to preserve Japan’s advanced manufacturing technologies. Ōtsubo asserts that there are many fields where Japanese firms excel: “Take functional materials, machine tools, molds, and precision processing, for instance. Although we don’t always realize how these technologies affect our daily lives, they are vital in manufacturing.”

The conglomerate posted more than ¥9.3 billion in sales in fiscal 2022, with its success leading many to see the company’s approach as a model for keeping small manufacturers from folding and preventing the loss of Japanese technological knowhow. Ōtsubo, for his part, sees the solution being on a global scale.

Yuki Precision CEO Ōtsubo Masato. (© Ikazaki Shinobu)

“The market in Japan is shrinking as the population declines,” he declares. “By expanding focus overseas, though, Japanese companies can preserve their technological edge even as demand falls at home.” He is confident that Japanese firms have what it takes to succeed in foreign markets.

“Take something as simple as peeling a sticker off a product,” he explains. “Often, those made overseas only partially come away, leaving the sticky back. A Japanese-made sticker, on the other hand, can typically be removed cleanly, without anything left behind.” Ōtsubo explains that this is due to the precision technology that went into the machine that made the sticker and blades that cut it. However, he warns that such expertise could be lost for good if economic conditions and other factors force manufacturers out of business. Although he admits that stickers are a small concern for most people, he stresses that even minor technologies can improve users’ experiences, leading to a better overall satisfaction.

Through Yuki Holdings, Ōtsubo is committed to preserving such distinct technologies, of which there are many in Japan, and boosting their presence on the global stage.

Corporate Data

Yuki Precision

Address: 370 Enzō, Chigasaki, Kanagawa Prefecture

CEO: Ōtsubo Masato

Business: Manufacture of precision machine parts for the aerospace industry and medical devices; production of electronic equipment

Capital: ¥35,000,000

Employees: 37 (including part-time workers)

Website: https://www.yukiseimitsu.co.jp/en/

(Originally Published in Japanese. Reporting and text by Sugihara Yuka and Power News. Banner photo © Ikazaki Shinobu.)