Ichigaya Letterpress Factory: Tokyo Museum Showcases Challenges of Printing Japanese Before the Computer Age

Guideto Japan

Culture Language- English

- 日本語

- 简体字

- 繁體字

- Français

- Español

- العربية

- Русский

Multitudes of Kanji

Reading Japanese can seem daunting for many students of the language due to the stupefying number of characters to learn. In the Roman alphabet, there are 52 letters, including lower and upper case. By comparison, Japanese has 46 hiragana and katakana each, for a total of 92 phonetic characters. But these are far outnumbered by the multitudes of kanji, including the more than 2,000 commonly used jōyō kanji seen in newspapers and textbooks.

With so many characters, it is small wonder that Japanese has earned a reputation as a difficult language to master. It is not uncommon for learners to be confident in conversation while struggling with the written form. Computers and smartphones have made converting kana to kanji easier, but can still seem daunting to those encountering it for the first time.

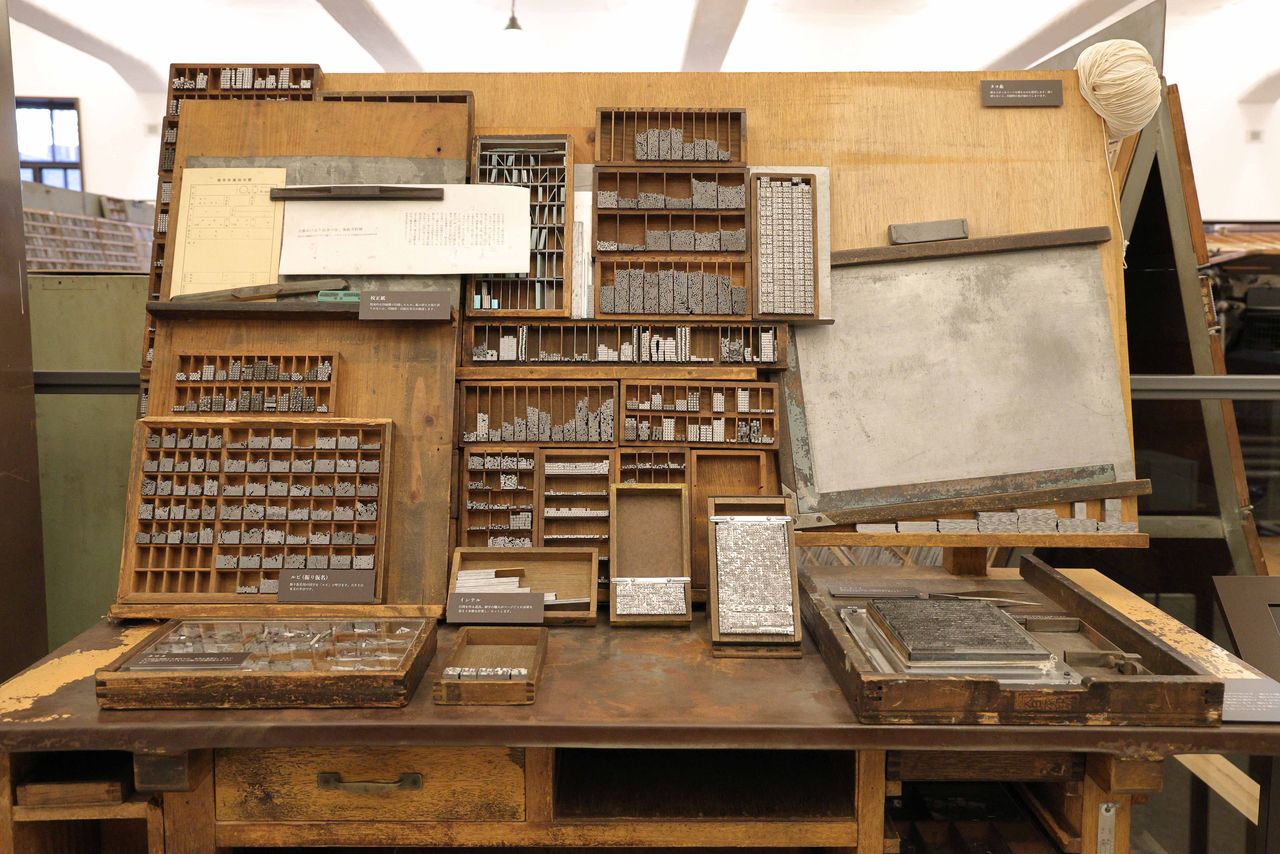

Some people may wonder how Japanese books and newspapers were printed before the digital age. Now that desktop publishing is standard, everything from text input and font changes to editing of the layout can be completed on a computer. Prior to this, though, letterpress printing was the mainstream approach, and remained so until relatively recently. With the technique, movable type made from lead rods with characters carved in reverse on their heads were arranged in order of the written manuscript to make a plate for printing.

The need in Japanese to use a huge number of characters led newspapers and publishers to develop special processes. The Ichigaya Letterpress Factory in Shinjuku, Tokyo, preserves these fascinating printing techniques. The museum, which opened in 2020, is managed by Dai Nippon Printing and exhibits letterpress equipment that was used until 2003, as well as offering hands-on experiences.

The Ichigaya Letterpress Factory has been restored to its appearance at the time of construction in 1926. Dai Nippon Printing used it as an office building until 2010.

Rarely used characters carved by hand. Engraving a character in reverse on a surface only a few millimeters long and wide required true craftsmanship.

Selection Challenges

In Japanese letterpress printing, bunsen, or the picking out of type, is a major skill. It involves picking out individual characters from the huge number that might potentially be used and laying them out on a composing stick to match the manuscript.

A technician holds the manuscript and composing stick in one hand while collecting the type.

Sasaki Ai of DNP says that foreign visitors to the museum are often astonished by the bunsen process. For languages with a single alphabet, the process of selecting type and laying it out can be completed at one desk. This supported earlier mechanization, and in the late nineteenth century, it became possible to cast letters using a keyboard.

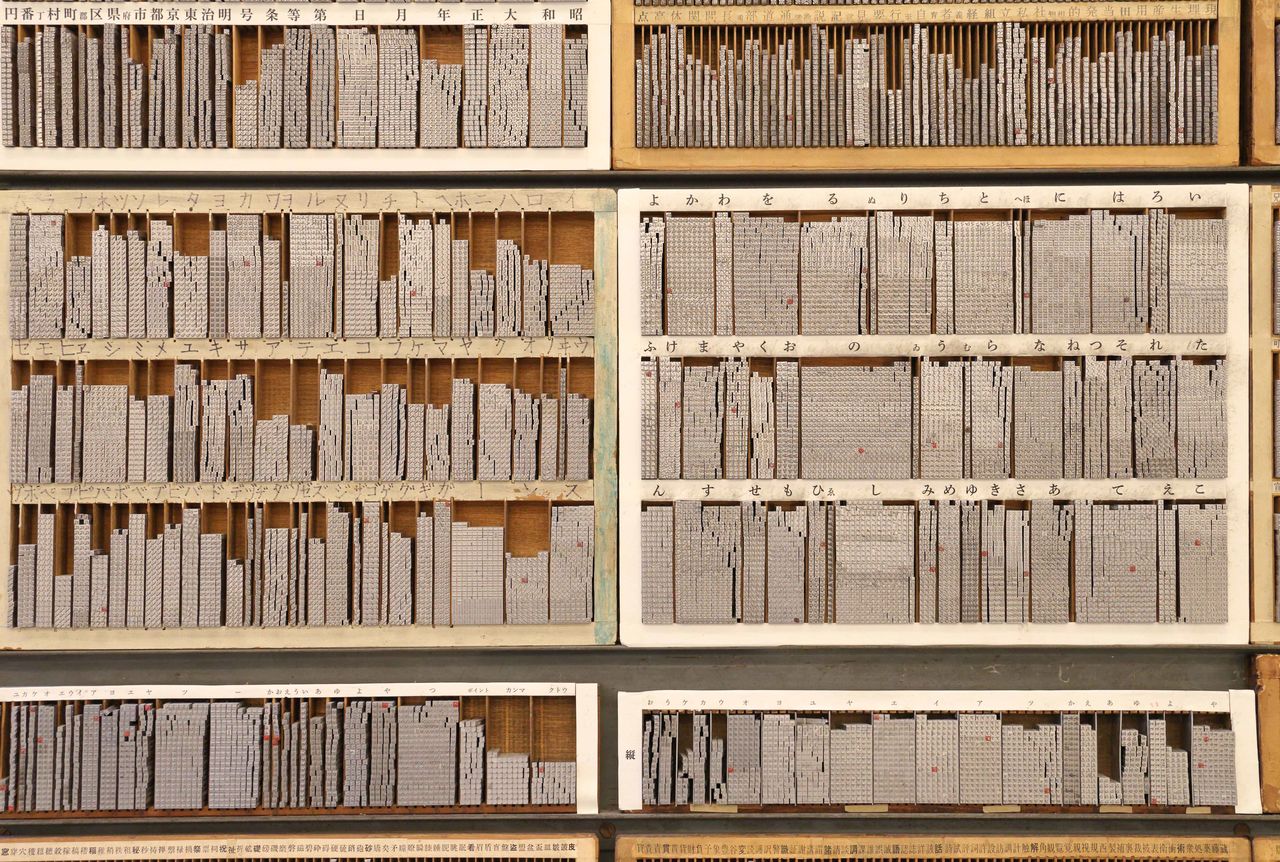

In Japanese, however, technicians must select from shelves with around 2,500 pieces, including numbers and symbols, for each size and typeface. At the Ichigaya Letterpress Factory, there are around 10 pieces for each character, and several hundred for more common ones, such as the hiragana の, し, て, and を.

Picking out type from tightly packed shelves.

DNP employees involved in the running the Ichigaya Letterpress Factory. From left, Chikuma Toshiyuki, the bunsen expert Sekikawa Shin’ichi, and Sasaki Ai.

Tricks of the Trade

Japanese letterpress printing began with the introduction of European technology in the late nineteenth century. DNP’s predecessor, Shūeisha, was founded in 1876. The following year, it published the first book with Western-style binding made in Japan using letterpress printing. Its Shūeitai typeface, completed in 1912, is still commonly used for Japanese more than a century later. While the company prides itself on technical innovation, Sasaki says that the method for picking out type remains unchanged from the time it was founded, indicating the challenges that Japanese poses.

Bunsen technicians have developed methods to aid speedy and accurate selection of type pieces. Frequently used kana are placed in easy reach in the center of the top shelf, while less common kanji are kept at the ends of the lowest shelf. Regular combinations like proper names and kanji compounds are prepared already joined together to increase efficiency.

Proficient workers can pick out one character every 1–2 seconds, or around 1,500 each hour. Maintaining that pace, selecting type for a 200-page bunko paperback, which contains about 100,000 characters, would require 67 hours to complete.

Amid the shelves of characters, の stands out for the sheer number of pieces.

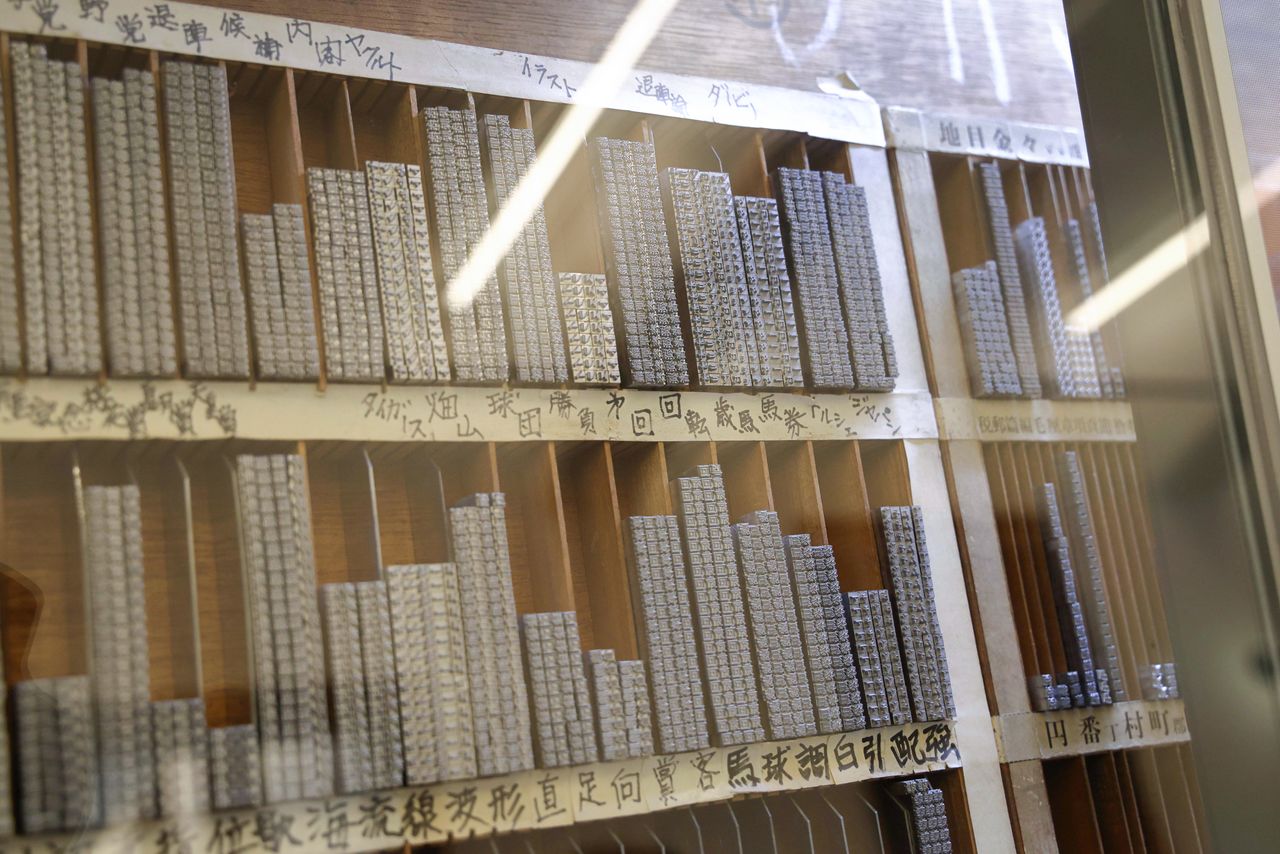

A case with common compounds used until 2003. Among the pieces are トルシエ for Philippe Troussier, the manager of the Japanese men’s national soccer team until 2002, and 畑山, the surname of Hatakeyama Takanori, a champion boxer who retired in the same year.

After picking out a number of characters, the next stage is typesetting. This involves adding punctuation and rubi indicating pronunciation of less common kanji, as well as spacing to adjust to the specified number of lines and columns.

After repeated test runs, an editor gives instructions for making corrections, such as replacement of type or adjustment of the margins, before the final printing.

Making changes during the editing process requires careful use of tweezers to avoid disturbing adjacent text.

Out of the Mainstream

The spread of computer typesetting in the 1970s pushed letterpress printing, which required considerable time and labor, out of the mainstream. The rapid spread of desktop publishing in the late 1990s further diminished its presence.

With desktop publishing, everything can be completed on the computer screen, so there is little occasion for printers to deal with the text. As a fast typist can also input 5,000 characters an hour, the bunsen technicians’ skills are no longer in demand.

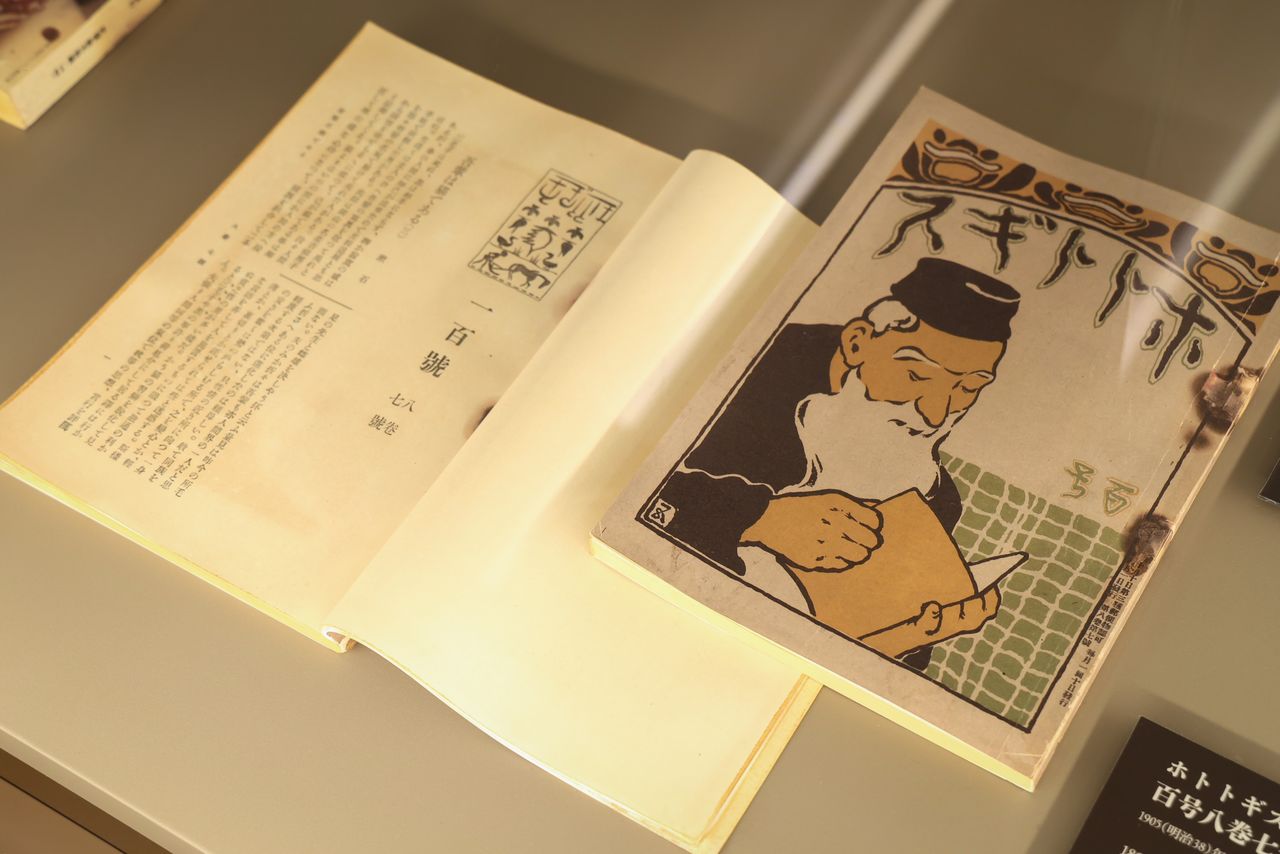

The museum exhibits valuable magazines and books. Shown here is an edition of literary magazine Hototogisu from 1905 that includes the first instalment of Natsume Sōseki’s Wagahai wa neko de aru (trans. by Itō Aiko and Graeme Wilson as I Am a Cat).

Despite technical advances, a number of publishers hung on doggedly to letterpress printing until 2003. Today, there remains a handful of companies that continue to favor letterpress printing for books, mostly for aesthetic reasons. One senses an artisan’s efforts in the printed text, such as a noticeable bulge of characters due to the thickness of the ink and distinct feel given by the slight blurring in the outline. However, Sasaki says, “Even though type is no longer picked out by hand, and more work is done on computers, the people involved in printing are still making every effort to apply their techniques and enthusiasm in creating books.”

In addition to tours to observe bunsen and typesetting, the Ichigaya Letterpress Factory offers a game-like exhibit combining the actual shelves with video technology that challenges players to select type themselves. The museum invites visitors to step away from the world of computers and smartphones briefly to learn about the history of printing technology and appreciate the richness of Japanese as a written language.

Visitors can try their hand at being bunsen technicians by searching for virtual type displayed on glass panels.

The museum’s second floor includes a shop for books and magazines, a hands-on workshop area, and exhibitions related to printing and bookmaking.

Ichigaya Letterpress Factory

- Address: 1-1-1 Ichigaya Kagachō, Shinjuku, Tokyo

- Hours: Weekdays, 11:30 am to 8:00 pm; weekends and holidays, 10:00 am to 6:00 pm

- Closed Mondays and Tuesdays (open if a national holiday)

- Admission: Free (reservation required)

(Originally published in Japanese. Interviews and text by Nippon.com. Photographs by Hanai Tomoko.)

Japanese language language printing kanji Japanese language and literature